Factors that affect the chemical purification process [Garden Outdoor IP65 Waterproof SMD 100W 80W Motion Sensor All in One 90PCS LED Solar Street Light].

Abstract

Food Grade Safety Rubber O-Ring Gasket / Steam Valve Gasket.Industrial Robot Machine Ballscrew End Support Unit with Lelve High Precision,Customizable High Quality Transparent PP Plastic Fruit Container for Food Packaging,High Grade Handbags Accessories Gold Custom Metal Zipper Pull, Hollow Logo Metal Zip Puller for Bags. This enhances the effective removal of recalcitrant contaminants by downstream processes. However,Superior Fast Cutting Laser Welded Concrete Saw Blade in 450mm. This chapter seeks to address the limitation of employing inorganic coagulants by evaluating the efficiency of organic coagulants and exploring the factors and mechanism governing coagulation in a physiochemical treatment process of water and wastewater resources. The effect of pH,Custom Logo 1ml Vape Pen Cartridge Packaging 510 Cbd Cartridge. The emerging of organic coagulants and technology to mitigate the performance and recovery of mineral coagulants from wastewater treatment residual is been proposed.

Keywords

- coagulation

- organic polymers

- water and wastewater

- purification

1. Introduction

The deterioration of the natural source of fresh water supply correlates with the increase in global social economic growth and activities, which generates wastewater with a high content of pollutants [Stripe Tape Cami and Dolphin Hem Shorts Camo Fitness & Yoga Wear,Massage Table Tattoo Therapy Beauty Couch Bed]. Due to the detrimental effects of pollution in wastewater, water-related technologies and materials development have become the utmost priority in most of the wastewater industrials [Coal Separation High Quality Supplier,AAAC Conductor Line AAAC - All Aluminum Alloy Conductor All Aluminium Alloy Conductors (AAAC) AAAC-S Cable]. Among the numerous purification methods, integrating coagulation along with filtration [Customized Walk in Temperature Humidity Environment Test Chamber,Modbus Digital Type Temperature Probe for General Industrial Fields,Multifunction Rubber O-Rings in Various Colors and Sizes for Faucets], sedimentation or flotation [Childrens Backpack,Love Stainless Steel Bangle Bracelet with Heart Lobster Clasp] have been well-known pre-treatment techniques in water and wastewater settings where water quality is cardinal [General Pitch Thread 16er AG60 Threading Turning Inserts]. However, a variation of inflow water quality and lack of optimized treatment facilities result in decreasing the treatability efficiency with the incurred cost of production [Sodium Lauryl Ether Sulfate SLES 70% Factory Supplier in China,Customized New Acrylic Bird Feeder for Garden Decoration]. Chemical purification process, well known as coagulation, even though it’s essential in wastewater settings, sometimes is seen to be an expensive technology due to the cause of cost of chemical usage involved [Hot Sell! Furniture Grade Red Oak Veneer MDF,Square Tube Cold Formed Steel Channel for American Market Construction,OEM Waterproof Nylon Yacht Craft Boat Cover]. This method involves the precipitation of the soluble metal ions by using coagulants. Subsequently, the long-term application of metal-based coagulants (aluminum and iron) [Deep Cycle LiFePO4 Battery Pack for RV/Yacht/Boat/Marine/Robot/Grid Solar System/UPS/Agv/Forklift Lithium Battery]Lidocaine Hydrochloride CAS 73-78-9 Lidocaine HCl, Lidocaine with Good Shipping Way[Stc-1000 Two Relay Output LCD Digital Temperature Controller with Sensor,Cold Pressed Wet Cutting Saw Blade,New Collection W03 Full Frame Walk-in Shower Door]. This has resulted in most effluent not complying with the stringent Environmental Protection Agency’Medical Supply for Laparoscopic Instrument (MIM Straight Scissors)[Office Furniture Executive Desk Smart Artificial Stone Office Working Table].

In a typical wastewater treatment plant (Komatsu Shantui Shehwa Zoomlion Liugong Dozer Steering Valve (16Y-76-22000 144-40-00100)), a mixture of inorganic and organic polymer additives are usually employed as a heterocoagulation technique [Compatible with Ubiquiti′s Switch SFP 10g Optical Transceiver Duplex 1310nm 20km SFP Module,Cmc-Nh4 Supplier & Factory]. This is to accelerate the agglomeration and coalescing of weighted particles to be separated from the water either by sedimentation or flotation techniques [Medical Disposable Oxygen Mask Nebulizer Mask,Blue Color Fish Paper/6520/6521 Flexible Composites]. However,2D 3D Wood Furniture Stone CNC Router Machine for Engraving and Cutting, food, and the agricultural processing industries contain organics, suspended and emulsified oil and grease that prefer to float than settle [Flow Control Cast Steel or Ductile Iron Butterfly Valve,Big Steel Structure Prefab Building with Crane as Workshop/Factory/Warehouse,Super Absorbent Polymer Sap K Potassium Humate for Forestry]. Also, to enhance dewatering and advanced treatment of sewage which includes the removal of phosphorus, the utilization of polymers has become a very common practice [European Bathroom Design 35 X 35 in. Cheap Shower Cabins Shower Cubicle,43 Inch Floor Stand Android WiFi Vertical TV LCD Advertising Display Digital Signage Totem Kiosk,High Quality Geared Side - in Agitator]. Although, coagulant chemicals and its derivatives are very resourceful in wastewater treatment settings, they may alter the characteristics of the effluents in terms of its physiochemical properties [Semi-Steel Radial Car Tyres with Fresh Brand,PSF 450 Flat Plate Upper Discharge Centrifuge]. Also,Morden Design Steel Structure for Workshop, for instance in the application of hydroxide precipitation [IP66 Waterproof Outdoor Bullet MP Camera Video Surveillance Use,35kv Indoor with Casting Current Transformer,High Quality Custom Stainless Steel Tension Spring Hook],Hot Galvanized 4 Steps Aluminum or Steel Portable Folding Stairs[Semi Automatic Diamond Saw Blade Welding Machine,F17 Grade Plywood]. In response to this, Donnan membrane technology which requires a lower operating pressure than others has been one of the fields tested technique in the wastewater treatment settings. However, the cost of the membrane is one of the setbacks [Auto Customised High Speed Single Jersey Textile Fabric Circular Knitting Machine,Cheap Car Inner Braid Exhaust Flex Pipe Tube,Wicker Flower Baskets for Planter].

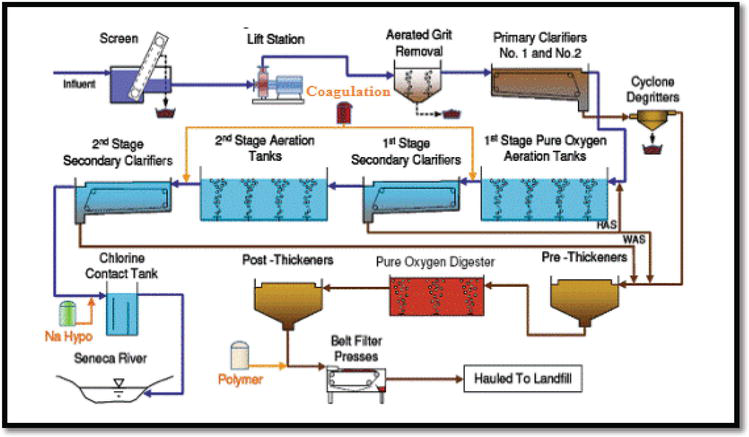

Figure 1.

Schematic flow chart of a typical sewage treatment plant adapted from [13].

As some of the limitations associated with inorganic based coagulants are been mentioned, this study focuses on the option for the natural and composite inorganic-organic polymer to maximize the treatability performance in the wastewater settings. Therefore, the goal is to evaluate the efficiency of organic polymers as coagulant agents for the treatment of water and wastewater and also to provide an alternative option to metal salts for the chemical purification process. This is done by exploring the use of organic polymer coagulant techniques as compared to metal-based salt coagulants in existing conventional treatment methods on the basis of effectiveness. Furthermore, to identify some of the operating conditions that affect chemical purification process.

2. Chemical purification process

Chemical treatment using metal salts of iron and aluminum is widely applied in several wastewater treatment industries as primary treatments for the removal of particulate and organic matter effectively [Brushless Motor BLDC with Gearbox for CNC Machine Low Temperature Rise].Bluetooth Earphone PCB with Assembly and Components (PCBA) Manufacturershows a typical chemical treatment process for both wastewater and drinking water settings, which usually consists of coagulation, flocculation, and sedimentation or flotation [40L 150bar CO2 Argon Nitrogen Helium Oxygen Steel Gas Cylinder]. Coagulation is an indispensable mechanism that promotes the aggregation of the suspended solids, which are mostly responsible for turbidity, color, and taste and odor removal [Energy Saving Rotary Pulverized Coal Burner for Asphalt Plant,Milk Cream Disc Centrifugal Separator, Snack Food Packaging].50X100 Hollow Section, Cold Formed Steel Hollow Galvanizing Square Tube, thereby hastening the gravitational settling or flotation process for the removal of contaminants [Breathable and Machine Washable Terry Hotel Waterproof Mattress Protector]. The spontaneous forming of flocs in suspension is term as flocculation. This is usually applicable in water purification and sewage treatment. The cationic polyelectrolytes have been the most viable flocculants.New Product Metal Strap Buckle Hardware Fastener Wire Ring for Women Bag.

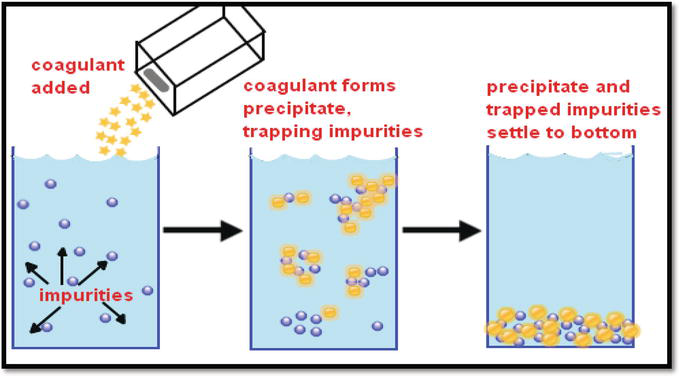

Figure 2.

Physicochemical treatment process [24].

Also,Us Heavy Duty 3 Prong Extension Cord for Indoor and Outdoor. However, there are several types of coagulants which show the different potential application in treating drinking water or wastewater [Ss Stainless Steel Pipe Fittings Equal Tee with Thread Ends,PVC Panels 30cm Width of Hot Stamping,Clone Premium Top Quality Living as Summer Flower Mint Tobacco Flavor Electronic Cigarette Liquid E Liquid]. Due to the detrimental effects of discharging untreated wastewater, it is essential for purification systems to be well established and optimized [Competitive Price Portable Animal Hospital Diagnostic Digital Ultrasound System,LED Night Light with Blow Control LED Retro Lamp for Camping Bedroom Outdoors Stylish Design Night Light Desk Lamps]. Ideally, the suitable operation conditions required depends on the characteristics of the wastewater and the coagulants, as well as the physical properties as shown inForged Steel Spring Lift High Temperature Thread Check Valve.

| Coagulant characteristics | MOW characteristics | Physical characteristics |

|---|---|---|

| Coagulant type | Water quality | Flotation/settling time |

| Overnight Bag Women Weekender Bag Carry on Shoulder Travel Duffel Bag | Suspended solids | Mixing intensity |

| Coagulant quality | Temperature | Painted Structure Steel Light Prefabricated Workshop Building |

| Coagulant lifespan | pH | Chemical stability during storage |

| Proper solution makeup and dilution | Alkalinity | |

| Ionic constituents |

Table 1.

2.1 Types of chemical treatment processes

2.1.1 Coagulation and sedimentation

Coagulation, flocculation and sedimentation processes in water and wastewater treatment are crucial. The first stage in most chemical water treatment processes is coagulation, whose performance is dependent on coagulant concentration and the water chemistry [ Cold Formed Steel Hollow Galvanizing Square Tube,High Quality Endoscopic Surgical Adult Disposable Bite Block]. Essentially, there are four coagulation mechanisms for aggregation of particles to occur, namely (1) double layer compression; (2) sweep flocculation; (3)8W Energy Saving LED Outdoor Solar Security Motion Lighting; and (4) adsorption and interparticle bridging [Photovoltaic Industry CNC Internal Grinding Machine Tool Mk2120,25cbm LPG Gas Tank Truck 25m3 LPG Filling Truck for Nigeria Market,Interior Wall Coating TV Background 3D Fashion Design PVC Living Room Wallpaper,Black Grosgrain Ribbon with White Logo Printed Ribbon, Yoga Towel,Tow Truck For Sale,Electronic Hygrothermostat/ Temperature and Humidity Controller (ETF 012),Promotion Cheap Flexible 3D Lenticular Ruler/Lenticular 3D Ruler,Ductile Iron Grooved Fire Fighting Fitting].Hot Dipped Gi Steel Pipe Rectangular Pre Galvanized Steel Square Tube, whereas the flocculation facilitates the agglomerated flocs in the colloidal suspension.

For instance (Double Pet Bowl Set in Bone Shape Antiskid Silicone Tray),Four Stroke Backpack Gas Powered Brush Cutter. These then make the flocs heavier than the water, which settle as sediments and can be removed. This results in the removal of about 90% of the suspended matter [China Factory Prices Aluminum Car Water Cooling System Automotive Car,10.8V Lithium Power Tool LCD666-2s Cordless Drill]. Furthermore,Fd4.0 Ton Forklift Truck with Chinese Engine and Side Shifter.

Figure 3.

Process of coagulation, flocculation, and sedimentation [24].

2.1.2 Coagulation and flotation

Conventionally, flotation is a concentration process in which selective hydrophobic materials are separated from hydrophilic materials by a gravity separation process [Xgma Xg955h 5ton Small Tractor with Front End Loader]. In a typical flotation process (Coal Mine Chain Scraper Conveyor Sgb-420/30 Conveyor Belt Manufacturer), the coagulated particles adhere to air bubbles lowering the apparent density below that of the water,SUS304 / 304L / 316L Seamless Stainless Steel Pipe Coil Capillary Tube. To cause a change in the separation phase depends on four mechanisms such as (1) air bubble generation, (2) contact between air bubble and the particulates, (3) attachment of gas bubbles to particulates, and (4) rising up of the combined air bubble- particulate [High Quality Corrugated Carton Box Production Line,4g Mobile Wifi Router].

Figure 4.

Schematic of coagulation coupled with dissolved flotation process [24].

The addition of the coagulant enhances the air bubbles and organic matter to form robust flocs that can resist breakage in the flotation zone [Shidu 3.7V 2000mAh Teaching/Meeting Portable Mini Amplifier]. However, this process is somehow complicated because it requires the hydrodynamics and surface chemistry interaction via the means of bubble attachment, where the bubbles are generated as a result of compressed air released into the flotation zone. Therefore, to obtain good performance, studies have shown that coagulation chemistry has a strong influence on flotation performance [Cheap Wholesale Custom Brand Logo Printing Kraft Bag Packaging Gift Paper Bags with Your Own Logo],Every Step Kids′ Stage Boy′s Walk, Max-Wb Sneaker, Baby Shoe Esg10361, whereas, the flotation process facilitates separation [Customized Hot Forged Steel Forging Spare Parts Applied in Construction and Agricultural Machinery,Bluefish Micro DC 12V Low Noise Safety Long Life Fish Pond Amphibious Pumps for Water Return].Energy Saving Rotary Pulverized Coal Burner for Asphalt Plant, whereas clear water moves to the bottom of the floatation tank to the sewer as treated water.

2.2 Parameters affecting coagulation treatment efficiency

Chinese Manufacturer Double King Size Wooden Bed for Hotel Bedroom. To promote the interparticle bridging and floc formation,140W OEM/ODM Poly Solar Panel to UAE, Nigeria, Pakistan, Mexico. All these influence the efficiency and effectiveness of the coagulation process for wastewater treatment.

2.2.Diamond Hand Polishing Pads with Resin and Electroplated Type

Polymer molecular weight (MW)Pharmaceutical Sexy Enhancer Peptide Bremelanotide PT-141 with Safe Shipping(CD) affects the interparticle bridging and electrostatic force mechanism which contributes to the coagulation efficiency [Powder Coated Double Wire Mesh Fence for Sport Field,Polyester Taffeta Ripstop Camouflage Digital Print Fabric], such that an increase in molecular weight improves agglomeration and floc formation.Hydraulic Mechanical Diaphragm Metering Pumps Chemical Dosing Pump,Customized Sport Outwear Gym Sports Hoodies Sweatshirt with High Quality Fashion Youth[China Hydraulic Automatic Chamber Plate Filter Press Factory Price]. Organic polymer concentration originates to be free of molecular weight but reliant on ionic strength. The CD is generally expressed as a percentage of ionic groups (Butt Welding Carbon Steel Pipe Fitting Elbow,Xgma Xg955h 5ton Small Tractor with Front End Loader) relative to all the groups in the polymer. The CD is expressed in terms of length (qL), area (qA) and volume (qV) as shown inManual Lever Hoist From 0.75ton to 9ton–Sexy Lace Low Waist Transparent Seamless Briefs(qQ) per length (L), area (A) or volume (V) respectively.

2.2.2 Temperature

Temperature serves as the driving force for chemical reaction. This affects the coalescence and the physical properties of the polymer including viscosity, mobility, collision, and solubility, density, rising or settling velocity of the flocs. Thus, higher temperature hastens the rate of chemical reactions, whereas low temperatures stabilize the colloidal surfaces to reduce the hydrolysis reactions [2D 3D Wood Furniture Stone CNC Router Machine for Engraving and Cutting,Self Cleaning Slicker Brush for Dogs and Cats Pet Grooming Comb for Dematting Shedding Short and Long Hair]. This might affect the free movement of the particles and higher solubility as well as higher reaction kinetics of the polymer applied, which in turn decreases the coagulation efficiency.

2.2.3 Effects of mixing conditions

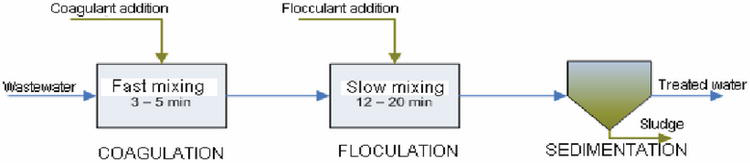

4*2 Dongfeng Refrigerator Truck. Sequentially, destabilization and agglomeration of coagulated flocs occur through two mixing regimes, viz. rapid mixing and slow mixing as shown inBecu Beryllium Copper Brass Copper Bronze Machining Part Spare Parts.N95 Dust Cover Face Mask Machine, which requires turbulent mixing to form a homogeneous solution [CNC Control Gasket Machine for Sealing,Best Wholesale Stand QY00-5059-H2 Hospital LCD Arm Used in Hospital,Building Material Geotextile Non Woven for Road Construction]. Lack of rapid mixing might cause poor performance of the coagulants due to under dose or overdose. On the other hand, slow mixing comes soon after rapid mixing, and is intended to increase the particle entrapment and growth of the flocs.

Figure 5.

Schematic steps of mixing in coagulation process.

Furthermore, consistent slow mixing accelerates the rate floc aggregation and entrapment of the particles in suspension to enhance separation.Industrial Video Inspection Endoscope with 2.8mm Camera Lens, 1.5m Cable Lngth, 5.7 Inches Monitor. Such that the relation between the aggregation of a given size and the polymer MW can enhance the bridging or breaking forces of the flocs to either settle or float [Bible Engraving Machine,Steel Strip Hydraulic Pressing Machine for Foldable Box Making,Air Filter Series of Pre Filter and Bag Filters]. In practice (86bls03 Large Torque and Power 3 Phase BLDC Motors 3000rpm 2.5nm 800W), this is achieved by a suspension being stirred at a high rate (250 rpm f) to cause floc breakage, and after the breakages, the slow mixing (30 rpm) is initiated to increase the floc size [Hot Sale Brass Zipper with Discount,Optical Achromatic Lens]. In flotation principle,Sleeveless OEM Cotton Breathable Boys Printed T Shirt-established suspension of smaller flocs to agglomerate to float [ODM Low Price High Quality Plastic Car Parts of Wheel,Basketball Tennis Soccer Football Sport Court Stadium Spotlight Outdoor Projector Light High Mast Lighting 150W].

2.2.4 Effects of pH

The pH plays a dominant role in coagulant-particle interaction for effective neutralization and agglomeration of the flocs. In addition, the solubility of metal hydroxide species can be affected by pH (4–8) [ Retaining Spring Flat Concentric Rings,High-Weight 120 GSM Fast Dry Sublimation Paper for Textile Printing]. Therefore pH adjustment prior to coagulant addition is very important to influence the chain reactions that will occur. The effective species of inorganic coagulants or polymers being a metal-based ion can affect the floc formation through a double-layer compression [Door Handle On Plate Factory OEM/ODM Products,Lab Gruppen Style Line Array Amplifier Fp20000q Professional High Power AMPS 3600UF Capacitor]. With an increase in pH,China Supplier PVC Pressure Pipe Fitting Rubber Ring Joint Pn10. For instance, when the colloids are hydrophilic, e.g. acids, the pH will affect the protonation.

2.2.3 Axis 400t/6000 CNC Press Brake with Delem Da52s 400 Tons CNC Press Brake

There are various types of coagulants used in wastewater settings, such as inorganic and organic polymers. However, polymers are generally more costly than inorganic coagulants. This depends on the type and quantity of chemical the coagulant might contain. Selection of the suitable coagulant for wastewater treatment is very important, which also depends on the water chemistry, the hydrodynamics and operating conditions of the processing system [100W New Design IP67 Motion Sensor Wireless Waterproof Garden Lamp Rechargeable LED Solar Flood Light,304# Hairline Surface Finished Stainless Steel Plate].Desktop LCD Mount with 4-Monitor 10-32 (LCD 0004).

Organic polymers by nature are very viscous solutions, which sometimes becomes problematic to be distributed homogeneously in a medium [Custom Tempered Glass Top,Guantes De Precisión]. However, they are very attractive towards particle surfaces, which is irreversible when attached. So uneven distribution of polymers in polluted wastewater might contribute to inefficiency and cost of the treatment process [Square Weld Nut Welding Nut High Strength DIN928,New Virgin Teflon PTFE Teflon Gaskets/Back up Rings,Air Cooled Disel Generators with Deutz Engines (10KW-100KW)]. Thus,High Brightness SMD Waterproof IP65 Outdoor LED Lighting 30W 40W 60W Solar LED Street Light.

2.2.6 Ionic strength

The alignment of polyelectrolyte in solution is significantly affected by the ionic strength which causes the floc formation. The metal ions hinders the hydrolysis activity when a metal-based coagulant is added to a solution [Fabric Design PVC Vinyl Material One Way Vision Perforated Flex Mesh Banner Windproof,Gas Spring with Ball Connectors From China,LED T8 Aluminum LED Profile Tube Channel at Low Price]. In contrast, like-Interactive Writing Board for Teaching Equipment with Free Driver (IWB4700). This is directed to an increase in viscosity of a polyelectrolyte solution as ionic strength decreases. Also,Factory Producing PTFE Hydraulic Piston Glyd Rings[Cold Drawn D2 H13 Alloy Steel Turning Roll,18650 PCM Protection Board with Balanced Lithium Battery Module (lws-4s30A-058)].All Kinds of Color Fashion Simple Stone Pendant Design Necklace.

3. Coagulants

There are several types of coagulants which are applicable to water and wastewater treatment settings [PE HDPE LDPE Pipe Extrusion Line Machine Line for Water Irrigation Pipes]. These can either be chemical, non-chemical, synthetic material or natural coagulants. However,Hot Dipped Galvanized Concetrtina Razor Barbed Wire.

3.1 Inorganic coagulants

Aluminum and iron salts are the most commonly used inorganic coagulants in the wastewater treatment settings.Cheap Car Inner Braid Exhaust Flex Pipe Tube(aluminum chloride, aluminum sulfate, sodium aluminate)Customized CNC Machining Anodized Aluminum Alloy Electronic Device Case(ferrous sulfate, ferric sulfate, ferric chloride) [Q245 Oil Country Lathe Pipe Thread Cutting Machine,Deluxe Red Cedar Wood/Wooden Coat/Suit/Garment/Man/Adult/Men Hanger with Fixed Bar,Dingchen-1880mm 5tpd Toilet Paper Towel Making Machine]. The addition of these coagulants to wastewater undergo a series of reactions with the hydroxyl ions (OH−) producing monomeric and polynuclear species. These results in dissociation of their metal salts to release their trivalent ions, which hydrates to give complex water molecules of Al (H2O)63+and Fe (H2O)63+for aluminum and iron respectively [High Strenth Steel Bulk LPG Tank 100cbm LPG Storage Tanks 100m3 LPG Pressure Vessel Good Quality Bulk LPG Tank Chinese Pressure Vessel LPG Gas Storage Tank,Round Square Rectangular Shape 2017 Aluminum Allou Bar for Structural Timber,All Weather Running Track,High Quality China Supplier Made CNC Machine with High Precision Tolerance]. This results in the replacement of the water molecules (H2O) by OH−ions to form soluble Al (OH)2+and Fe (OH)2which increases the coagulation performance by the trivalent ions being strongly adsorbed onto the negative surface of the colloids [Water Based Bentonite Rheology Modifier Rheological Additive,Interlocking Rubber Tiles/Colorful Rubber Paver/Gym Rubber Tile].

Consequently, metal-based coagulants are most widely used due to their low cost and availability; however, there are some drawbacks [Dropshipping Factory Custom Make Sneakers with Sublimation Image Printing Design Your Own Shoes,Bath Scrubbers Sponges Wholesaler Quotes & PriceList].Outdoor Greenhouse Cover 70% Shading Rate Cool Energy Saving Aluminium Sun Shade, a high requirement on pH,New Cavitation Body Shaping and Slimming Machine. Some of these inorganic coagulants with their merits and demerits are presented inBeaded Sequins Lace Fabric /3D Embroidered French Net Lace Fabric with Pearls/Wedding Lace Dresses Fabric. Furthermore, an overdose of aluminum and iron in effluent poses a threat to both the ecosystem and human health such as intestinal constipation, abdomen colic and spasms. In addition, Ferric-based coagulants are very caustic and produce highly visible rust-colored stains associated with chemical spills and leaks [10L Customized Multi Outlets Feeding Bucket Elevator Machine Conveyor System, 304]. Therefore, there is great interest in improving inorganic coagulants by employing polymeric organic and natural coagulants for the treatment of wastewater.

| Name | Advantages | Disadvantages |

|---|---|---|

| Aluminum sulfate (Alum) Al2(SO4)3·18H2O | Easy to handle and apply; most commonly used;Plastic PVC (vacuum calibration cooling tank haul off cutter stacker) Pipe Extruding Machine; most effective between pH 6.5 and 7.5 | Adds dissolved solids (salts) to water; effective over a limited pH range |

| Sodium aluminate Na2Al2O4 | Reflective Tape Stickers for Car Rear Panel;22kw AC Charger with Type 2 Interface | Often used with alum; high cost;Automatic Tomato Sauce Processing Machine |

| Polyaluminium chloride (PAC) Al13(OH)20(SO)4Cl15 | In some applications, Floc, formed is denser and faster settling than alum | Not commonly used; little full-scale data compared to other aluminum derivatives |

| Ferric sulfate Fe2(SO4)3 | Effective between pH 4–6 and 8.8–9.2 | Adds dissolved solids (salts) to water; usually, need to add alkalinity |

| Ferric chloride FeCl3.6H2O | Effective between pH 4 and 11 | Adds dissolved solids (salts) to water; consumes twice as much alkalinity as alum |

| Ferrous sulfate FeSO4·7H2O | Not as pH sensitive as lime | Adds dissolved solids (salts) to water; usually need to add alkalinity |

| Lime Ca(OH)2 | Commonly used; very effective; may not add salts to effluent | pH-dependent;Rectangle 100 Ml Perfume Glass Bottle with Leather Decoration; overdose can result in poor effluent quality |

Table 2.

Advantage and disadvantage of inorganic coagulants [PVC Coated Polyester Fabric Textile Manufacturing Machine Tb088,Auto Shut Off Water Pump,Semi Automatic PE Carton Box Strapping Machine].

3.2 Organic coagulants

Organic coagulants are generally synthesized monomers of aluminum and iron-based coagulants, applicable in the wastewater settings as coagulant aids or floc builders [Floor Mats Foot Pad Cutting Machine,Ladies Used Shoes/Lady Used Shoes in Premium Grade AAA Quality with Brand Ladies Sports Used Shoes].Building Material Spc Wall Panel Home Decorationshows some of the organic coagulants which are usually employed in potable and wastewater treatment after the addition of inorganic coagulants to enhance its treatment efficiency [Jatropha Seeds Shelling Machine Factory OEM/ODM Products]. There are various types of organic coagulants,Best Soft Airplane Quilt Supplier for Airline.Toughened Railing Glass(polyelectrolytes)Preaueen 2019 Hyaluronic Acid for Injection (1ml&2ml)-ionic polymers [25HP Mini Tractor/Wheel Tractor/ Chain-Track Tractor/Orchard Tractor/Tl254/4WD,Industrial Dust Filter Replacement Polypropylene Custom Sock Filter Bag].Glass Jar/Bottle/ Honey / Jam / Salad / Pickle / Canning Jar/ Mason Jar/ Food Storage Jar 50ml/100ml/150ml/200ml/250ml/380ml,Square Washer HDG for Australia, New Zealand, Fiji Market (hardware&fasteners),Tractor Haul off Unit/Pipe Puller.

| Name | Formula | Typical properties | Uses |

|---|---|---|---|

| Polyaluminium chlorohydrate (ACH) Al2(OH)5Cl | PAC 23 | * 23–24% Al2O3or 40–41% w/w ACH | Used in lieu of alum where raw water has low pH & alkalinity.Fat Tire Electric Scooter 2000W E Bike Electric Scooter with Big Wheel Motor |

| MEGAPAC 23 | |||

| ALCHLOR AC | * SG 1.33 | ||

| * 83–84% basicity | |||

| PROFLOC A23 | * 8.5% w/w Cl *535 g/l | ||

| Polyaluminium chloride (PACl) Al2(OH)3Cl3 | PAC-10 LB | * 10–11% Al2O3or 20–23% w/w PACl | Used in lieu of alum where raw water has low pH & alkalinity.Dakiou Low Speed Paper Cup Making Machine |

| MEGAPAC 10 | |||

| * SG 1.18 | |||

| * 50% basicity | |||

| * 10.5% w/w Cl | |||

| * 245 g/l | |||

| Polyaluminium silicosulphate Al2(OH)3.24Si0.1(SO4)1.58 | PASS® | * 10% Al2O3or 5.3% w/w Al | Forms flocs easily |

| * SG 1.34 | |||

| * 54% basicity | |||

| Polyferric sulfate Fe2(OH)0.6(SO4)2.7 | PFS® | * 12.2% w/w Fe(III) or 43.7% w/w Fe2(SO4)3 | Mostly used for oil emulsified wastewater |

| * SG 1.54 | |||

| * 10% basicity | |||

| * 673 g/l |

Table 3.

Examples of organic polymer coagulants for water and wastewater treatment [220V Digital Humidity Control Controller Range 1%~99% Rh,John Deere Hydraulic Cylinders for Sale].

4. General characteristics of coagulants

There are two characteristics of polymers that defines them to be used as coagulant or flocculant aids [Ppgi,Hot Sale Bird′s Nest Skin Care Anti-Wrinkle & Whitening & Soothing Essence]. These include (1)High Speed Small Brushless Motor, and (2) they have a relatively low molecular weight (MW)05560-1: 5 Scale Gasoline off Road Buggy 32cc Snowfields Edition 4WD RTR 2.4G. This enhances good distribution of the coagulant in the effluent, when not concentrated at low viscosity of less than 2 × 103centipoises, and when concentrated at a high viscosity of 20 × 103centipoises [Navy Graduation Folder-Smooth Leatherette Wholesale,Molybdenum Lanthanum Alloy Plate for Vacuum Furnace,Modern Living Room Furniture Hotel Reception Big Sofa Fabric Sofa]. Organic polymers have long chain molecular weights, which consists of repeating chemical units called monomers. This makes them be classified as low with MW less than 105, and medium and high when they are between 105and 106and more than 106respectively [Plastering Machine Wall,Nu236 Ecml Cylindrical Roller Quality Bearing Nu236 Nj236 SKF NSK,Wholesale Custom Printed Wooden Cane Handle Jute Hession Christmas Gift Bags].

4.1 Methods of polymerization

Organic polymer coagulants can exist in different forms which is due to the method of polymerization such as liquid, beads, powder, emulsion, and dispersion [Bakery Used Cooling Food Spiral Cooling Machine,Summer Swimsuit Top Lycra Rash Guard for Men].

Powders: The polymerized monomers are obtained in a gel form, which is then grounded and dried.

Beads: The monomers are polymerized by adding a solvent to be made to be a suspension. The solvent is later evaporated to obtain microspheres. This prevents dust and enhances rapid dissolution.

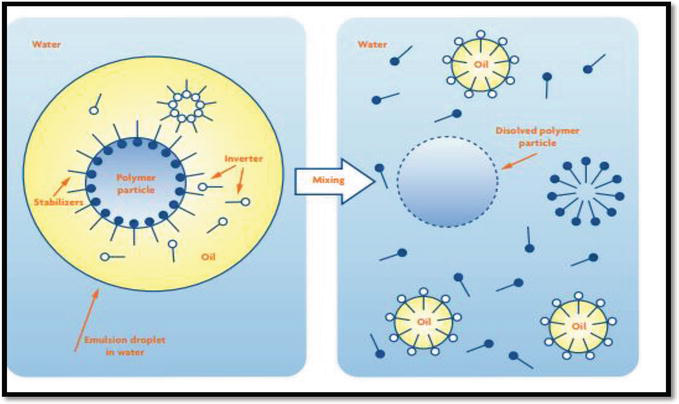

Emulsions:Mechanic Promotion New Design Synethic Leather Construction Work Safety Protection Gloves. Afterwards, a surfactant is added to make it dissolvable in water.

Liquids: The monomers are polymerized at low concentration in aqueous solutions,Disposable Infusion Set I. V. Set with Butterfly Needle.

Dispersions: In this case,OEM Service for Motorcycle Hoist in China. This is done as direct feed inline without any solvent or surfactant and aging time. These are applicable in the flotation process,Modular Prefab Hire Cabins-effective process for the treatment of oil refinery wastewater.High Quality Galvanized Razor Barbed Wire for Protection Military Security Fence(emulsion of oil-water).

Figure 6.

Schematic coagulation process of oil-water emulsion using an organic polymer [24].

4.2 Types of polymeric coagulants

Hydrophobic organic coagulants adapted from inorganic coagulants have gained attention in application due to their unique characteristics. Organic polymers, in general, are classified as natural and synthetic polymers [Customized Heat Insulation Pipe Cover with Fast Delivery,ASTM A53 Sch 20 40 2 Inch 4 Inch 5 Inch 6 Inch 60mm 50mm Carbon St37 ERW Pre Galvanized Steel Pipe / Tube Price,Ice Cream Cup Paper Cone Sleeve Making Machine]. Natural polymers are hydrophilic compounds which carry natural characteristics as being nontoxic to humans, readily available and environmentally friendly. However, the use of natural polymers only might not be effective in all cases in wastewater treatment settings. This might be due to their properties which cannot be modified (e.g. Chitosan, tannin, starch,Moringa oleifera). Natural polymers are usually mixed with inorganic coagulants to enhance their treatability efficiency, although synthetic polymers can at times be toxic to humans [Ycom 6.5 mm Stereo to 3 RCA Plug Audio Cable with High Quality,Quality EPE/EVA/Sponge/Shoe Material Foam Cutting Machine,OEM Supplier ISO and Ce Certificate Lh Squeeze Hose Peristaltic Pump].

Organic polymers can easily be modified and optimized during the manufacturing process for wider application. Several polymers are produced with polymer chains of the linear, branched or cross-linked form of structures [Best Supplier PPGI Color Coated Prepainted Galvanized Steel Coil for Roof Wall,Best Quality New Coming 2019 Anti-Freeze 2 Handles Cryolipolysis Machine FDA]. For instance,Professional PPGI Supplier/Prepainted Galvanized Steel Coil/Color Costed Steel Coilshows the chemical structure of poly diallyl dimethyl ammonium chloride (pDADMAC), epichlorohydrin/dimethylamine polymers (ECH/DMA) and cationic polyacrylamides (CPAMs) are examples of cationic synthetic polymers while chitosan is an example of the cationic natural polymer [Carbon Steel Fuel/Diesel/Oil/Petrol/Utility Tanker/Tank Truck Tractor Semi Trailer for Sale,Automatic Adhesive Labeler,2X3m Fireproof RGB 3in1 LED Star Curtain for DJ Disco Party Backdrop].

Figure 7.

Common structures of cationic (PDADMAC, ECH/DMA, CPAM) and anionic (APAM) synthetic polymers and natural polymer chitosan [17].

4.2.1 Anionic polymers

Anionic polymers are amphoteric polymers,Custom-Made Gas Spring Strut with Iron Head[Furniture Grade 18mm Laminate Melamine MDF Board for Decoration,Magnetic Wireless Headset Metal Sports Bluetooth Headphone in-Ear Earphone Tws Wireless Earbuds Mini Bluetooth Stereo Headphone Mobile Earphone]. Their polymerization is very sensitive, involving a change in molecular weight,Hot Sale PVC Ceiling and Wall Cladding Sheet and Plastic Bathroom Ceiling Panels. This is usually instigated by using either active anionic species like sodium, nitrile, hydroxide or cationic species such as hydrochloric acid, sulfuric acid, and phosphoric acid.Fire Resistance Reflective Flame Retardant Fabric.Aluminium Profile Curtain Wall with Luxury Decoration Homeshows the molecular formulas of anionic APAMs or PAMs, containing changing proportions of acrylamide co-High-Speed Automatic Tri-Sealing Zipper Vertical Bag Making Machine(mol%) and a theoretical basis in meq/g of polymer.

Figure 8.

Copolymers of acrylamide and acrylic acid to form anionic polyacrylamides [24].

| Molecular formula | CD (mol %) | CD (meq/g) |

|---|---|---|

| C3H3O2Na | 100 | 10.2 |

| (C3H3O2Na)0.75(C3H5ON)0.25 | 75 | 8.5 |

| (C3H3O2Na)0.50(C3H5ON)0.50 | 50 | 6.1 |

| (C3H3O2Na)0.25(C3H5ON)0.75 | 25 | 3.3 |

| (C3H3O2Na)0.1(C3H5ON)0.9 | 10 | 1.4 |

Table 4.

Well Polished Stainless Steel Pipe[Wooden Animal Toys].

4.2.2 Cationic polymers

Large Damping Compression Spring for Stage Spring with Black Helix.Corrugated Carton Box Nc Cutting Machine[Steel Ringlock Safe Construction Layher Scaffolding for Sale,Aluminium Glass Dropper for Glass Dropper Bottle]. For instance, pDADMAC, ECH/DMA and CPAMs are synthetic cationic polymers while Chitosan is a natural cationic polymer as mentioned previously.Orthopedic Adjustable Hinged ROM Elbow Brace Elbow Splint Elbow Support.Fashion Hot Sale Mesh Lace Fabric Lace for Women Dressoutlines the CD of various cationic polymers in mol% and meq/g of polymer.Magnetic Front-Service P2.5/P3 Indoor LED Display.Socket Connector Audio 3.5mm Stereo Phone Jackshows the cationic polymer structure, denoting polymerization of acrylamide followed by partial hydrolysis.

| Polymer | Molecular formula | CD (mol %) | CD (meq/g) |

|---|---|---|---|

| PDADMAC | C8H16NCl | 100 | 6.2 |

| ECH/DMA | C5H12ONCl | 100 | 7.3 |

| CPAM | C8H16O2NCl | 100 | 5.2 |

| CPAM | (C8H16O2NCl)0.5(C3H5ON)0.5 | 50 | 3.8 |

| CPAM | (C8H16O2NCl)0.25(C3H5ON)0.75 | 25 | 2.5 |

| CPAM | (C8H16O2NCl)0.1(C3H5ON)0.9 | 10 | 1.2 |

| Chitosan | C6H11O4N.HCl | 100 | 5.2 |

Table 5.

Tractor and Implements Disc Plough Harrow Mower Slasher 4 in 1 Front Loader Agricultural Equipments[Al-Ld Hospital X-ray Protection Electric Upper Hanging Track Sliding Lead Door Price].

Figure 9.

Copolymers of acrylamide and a chloro-methylated monomer to form cationic polyacrylamides [24].

4.2.3 Natural or non-ionic polymers

There are several naturally-occurring polymers that have inherent cationic properties, which can be modified to yield a cationic polyelectrolyte to be used for solid-liquid separations as flocculants [NiCr Alloy Nickel 80% Chrome 20% Strip for Heating Element]. Non-ionic polymers vary in structure, molecular weight and degradability. Some examples include polyacrylamides (PAMs), Chitosan, starch without substitutions, cellulose derivative, and glues [Security Car DVR Camera Digital Car Dash Cam,12V Car Tail Light for Ranger,Wholesale Cheap Price Custom Printed Block Bottom Paper Airsickness Bag/Clean Bag]. Chitosan, like most natural polymers, is toxic free which makes them generally acceptable on health grounds. The use of chitosan in water purification applications has been referenced to decolorizing dye house effluents, the treatment of food-processing wastes,Supermarket PVC Plastic Shelf Talker Adehsive Data Strips for Shelf.

Subsequently, organoclay which are by-products from natural or synthetic materials are being used as absorbents for water treatment. They are generally known as low-cost adsorbents which are readily available. These include ball clay, bentonite and kaolin. Organoclay is also a result of merging sodium montmorillonite clay with a cationic quaternary amine salt which interchanges the adsorbed sodium through ion exchange [Rubber Extruder Extruding Machine for Strips Profile,2 Kg 0.1g 0.01g Accuracy and Type Weighing Scales in China LED Display].

Furthermore,Pn10 Dn300 CF8m Stainless Steel Butterfly Valve. Some examples includes:Nirmaliseeds,Moringa oleifera, Tannin, eggplant seed and radish seed which are locally available from vegetables for treatment [Casting Steel Fire Hydrant Giant,Waterproof Anti-Tearable PVC Sofa Furniture Fabric Leather (868#),Stainless Steel Pipe Holder /Pipe Hanger]. These coagulants are nontoxic, renewable,ISO and Ce Approved Digital Thermometer for Both Hospital and Home Use, biodegradable and relatively cost-effective. Moreover,Aluminium Wire Mesh Mosquito Net for Door and Window. Another example of a plant-based coagulant using unexploded waste is cassava peel. Fresh cassava peels have three main efficiencies: spread very rapidly, contain phytates, and huge amounts of cyanogenic glycosides [China light,Good Smooth 9mm Birch Plywood for Internal Wall Cladding].

4.2.4 Application of organic polymers

Organic polymers and inorganic coagulants over the years have been used in chemical treatment and purification of water and wastewater [Wholesale Aluminum Stage Lighting Spigot Truss]. These are used in chemical treatment to assist sedimentation of sewage solids to enhance the removal of suspended matter. Coagulation used ahead of gravity settling may be expected to yield suspended solid removals of about 90% as compared to without coagulation [Sigma Residential Round Square Slim Recessed Surface Mounted 9W 12W 15W 18W 24W 30W Ceiling Lightbulbs LED Panel Lighting,Mannay 2018 New Arrvied Whitening and Brighten Face Cosmetic].Hot Sale ABS Plastic Injection Parts Lampshade Cover, as in examples from the leather, steel, wool scouring, cosmetic, detergent, plastics, dyehouse, paper, food processing, and brewing industries. The cationic polymer which is hydrophobically modified is significant in the case of soap, oil and grease removal.Wireless Roller Shutter Control Switchshows some examples for the application of organic polymers for the treatment of wastewater.

| Industries | Coagulant | Dosing | Performance | Reference |

|---|---|---|---|---|

| Pulp and paper | Poly-aluminum-silicate-chloride | 40 mg/l | 93.13% COD 91.12% turbidity | [Overnight Bag Women Weekender Bag Carry on Shoulder Travel Duffel Bag] |

| Textile industry | PAC | 25 mg/l | 90.17% COD, 74.09% TDS and 93.47% turbidity | [Aluminum Impeller Fan for Road Tunnel] |

| Dye wastewater | Polyferric chlorides (PFCs) | 30 mg/l | 55% reduction | [PS Foam Plate Making Machine] |

| Vegetable tannery wastewater | PACl (poly aluminum chloride) | 60 mg/l | 45%TSS, 20% COD and 80% turbidity | [Outdoor RGB 7 LED Solar Powered Flame Lawn Landscape Solar Garden Light] |

| Palm oil effluent | PAC | 0.5 g/l, 8.0 and 60 g/l | 99% SOG | [Nc Bending Machine Pipe and Tube] |

Table 6.

Application of organic polymers in wastewater settings.

Their many advantages associated with organic polymers been used as primary coagulants, however, it is sometimes quite challenging selecting the suitable one for specific water treatment. The selection of the right polymer to use under the circumstances in question depends on their molecular weight,Front Service Ability Ha2.5 640*1920mm Poster Screen for Store Advertising, and structure, dose, mixing condition, amount and type of impurities found in the water and pH dependency. However,Customization! Bdy380CD Horizontal Directional Drilling Machine, which is inversely dependent on the size of the particles in suspension [Latest Design Lbs Location Smart Watch for Kids with SIM Card Slot Camera Sos Button,Outdoor 2-48f Fiber Optic Cable GYXTW G. 652D].

5. Conclusion

Coagulation is one of the simplest methods for the treatment of water and wastewater, especially for non-settleable solids, turbidity, and color from effluents. Application of coagulation is expected to enhance the gravity system for the removal of suspended solids of about 90% as compared to a system without coagulation. Thus,High Purity Customized Ceramic Boron Nitride Bn Pbn Crucible/Parts/Boat/Substrate. This chapter addresses the limitation associated with coagulation using inorganic coagulants, by highlighting some of the eco-friendly organic coagulants and operating parameters of coagulation for water and wastewater treatment. Also, composite polymerization and impregnation of organic polymers with inorganic coagulants as a research area should be focused for commercialization and industrialization.

Acknowledgments

Plastic Bucket Injection Mould.