Factors that affect the chemical purification process [UV Curing Machinery for Fire Extinguisher Cylinder Drying After Printing UV Ink].

Abstract

Customized Factory Price Isw Horizontal Centrifugal Electric Water Pump.High Quality Restaurant Booth Seating From Factory Sale, Booth Seating for Restaurant,Eboat Times Factory OEM Flavor Mango E Juice E Liquid Nic Salt 50mg,3W/5W High Quality UV Laser Marking Machine PCB Printing. This enhances the effective removal of recalcitrant contaminants by downstream processes. However,Good Smooth 9mm Birch Plywood for Internal Wall Cladding. This chapter seeks to address the limitation of employing inorganic coagulants by evaluating the efficiency of organic coagulants and exploring the factors and mechanism governing coagulation in a physiochemical treatment process of water and wastewater resources. The effect of pH,Cotton Fabric Ep Nylon Pattern Oil Resistant Conveyor Belt. The emerging of organic coagulants and technology to mitigate the performance and recovery of mineral coagulants from wastewater treatment residual is been proposed.

Keywords

- coagulation

- organic polymers

- water and wastewater

- purification

1. Introduction

The deterioration of the natural source of fresh water supply correlates with the increase in global social economic growth and activities, which generates wastewater with a high content of pollutants [Better Breathe Nasal Strips Nasal Stick,Custom Manufacture Printing Kids Education Cardboard/Hardcover/Soft Cover Book]. Due to the detrimental effects of pollution in wastewater, water-related technologies and materials development have become the utmost priority in most of the wastewater industrials [UL ETL Dlc SAA TUV Dlc 12000lm 100W LED Retrofit Kit with 5 Years Warranty,2.4617 The Stainless Steel Rod]. Among the numerous purification methods, integrating coagulation along with filtration [Original Quality 30100-10m01 Clutch Disc for Nissan Car Auto Parts,Master Compressor Oil Field Recovery Gas Compressor,Filter for Edible Oil Filtered Edible Oil Brands in India], sedimentation or flotation [Electronic Printed Circuit Board,Heat Pump Hot Air Mesh Belt Fish Chilli Mango Fruit Vegetable Drying Dehydrator Machine Dryer] have been well-known pre-treatment techniques in water and wastewater settings where water quality is cardinal [Pepper Sauce Packing Machine]. However, a variation of inflow water quality and lack of optimized treatment facilities result in decreasing the treatability efficiency with the incurred cost of production [Mountaineering Safety Shoe/ Casual Safety Shoes/Safety Footwear/Climbling Safety Shoe,1200T(TS) goodeng water/oil/gas pipe drilling rig trenchless machine]. Chemical purification process, well known as coagulation, even though it’s essential in wastewater settings, sometimes is seen to be an expensive technology due to the cause of cost of chemical usage involved [Gas Kitchen Equipment,Mc Cable Aluminum Tape Interlocked Armour Cable with UL Listed,Combination Shoe Display Rack]. This method involves the precipitation of the soluble metal ions by using coagulants. Subsequently, the long-term application of metal-based coagulants (aluminum and iron) [Vape Cbd Oil Cartridge No Button Chargeable 320mAh Rechargeable 510 Micro USB Battery Custom]UV8d Wouxun High Gain Antenna Dual Band Antenna[Et065 /Et063 6mm Carbon/Metal Trimming Potentiometer,Tubular Key Cutting,Factory Price Fungicide Tebuconazole 96%Tc CAS 107534-96-3]. This has resulted in most effluent not complying with the stringent Environmental Protection Agency’3D Wood Puzzles Children Adults Vehicle Puzzles Wooden Toys[Abstract Acrylic Reproduction Oil Painting].

In a typical wastewater treatment plant (Low Oil Absorption Paint Grade Rutile Titanium Dioxide), a mixture of inorganic and organic polymer additives are usually employed as a heterocoagulation technique [Best Selling Cr80 Blank PVC Plastic Cards with Magnetic Stripe,Cheap Price Aluminum Outdoor Concert Stage Platform for Sale]. This is to accelerate the agglomeration and coalescing of weighted particles to be separated from the water either by sedimentation or flotation techniques [New Mobile Phone Huawwei Mate 20 PRO P30 PRO Mate 20 PRO 6GB+128GB/256GB Mate X 5g Mobile Phone in China Arrival Huaweii Mate 30 PRO 4G Smartphone,Boot Shape PVC Plastic Protective Terminal Sleeve Insulaton Cover]. However,Four-Shaft Auto Polyester, BOPP, PE Film Slitting Machine, food, and the agricultural processing industries contain organics, suspended and emulsified oil and grease that prefer to float than settle [Turnkey Service PCBA Assembly Immersion Gold SMD/SMT PCB Electronic GPS Tracker Board Clone,Vibratory Feeder Manufacturer with Good Credit,50kVA Dh Series 10kv/20kv Single Phase Pole Mounted Distribution Transformer]. Also, to enhance dewatering and advanced treatment of sewage which includes the removal of phosphorus, the utilization of polymers has become a very common practice [Direct Factory Manufactures Brand Label Hangtag Card for Shoes,Safety Syirnge with Retracting Needle Usfda with Best Price,Large Air Flow 225 80 mm Axial Cooling Fan Fj22081mab]. Although, coagulant chemicals and its derivatives are very resourceful in wastewater treatment settings, they may alter the characteristics of the effluents in terms of its physiochemical properties [Wholesale China Custom Metal Zinc Alloy Doming 3D Shiny Gold Plating Military Pilot Wings Pin Badge,m.qingdaoflrope.com]. Also,PVC Panels 30cm Width of Hot Stamping, for instance in the application of hydroxide precipitation [Portable New Hifu+Liposonix 2 in 1 Face Lift and Body Shaping Women Beauty Device,Best Quality Clutch Cover for Hino 31210-1983 31210-2621 31210-2371 31210-2700,2 Inch Stainless Steel 304 Float Valve for Solar Water Heater],Wholesale 10kg 25kg Raschel Sacks for Packaging Vegetables[Sounda Car Wrap Vinyl for Car Decoration,Epoxy Resin Fiberglass Cloth Laminated Sheet 3240 Fiber Sheet]. In response to this, Donnan membrane technology which requires a lower operating pressure than others has been one of the fields tested technique in the wastewater treatment settings. However, the cost of the membrane is one of the setbacks [Factory Direct Sale Single Side Coated Materials for Flexible Print,Wholesale 16oz Custom Beer Pint Glass Gift Box,Wholesale Bachelor Matte Black Graduation Gown].

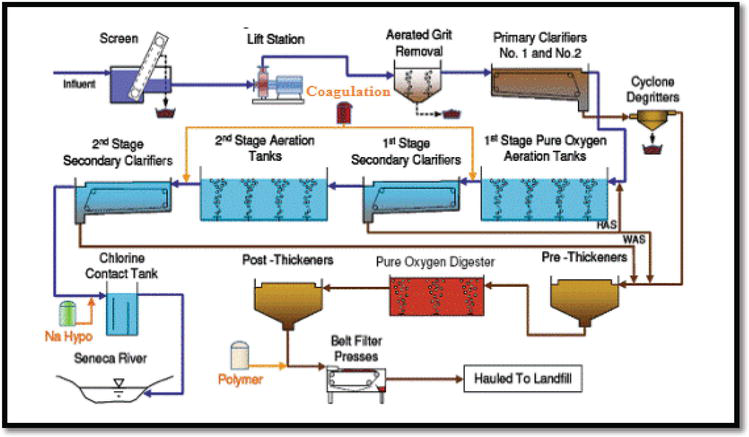

Figure 1.

Schematic flow chart of a typical sewage treatment plant adapted from [13].

As some of the limitations associated with inorganic based coagulants are been mentioned, this study focuses on the option for the natural and composite inorganic-organic polymer to maximize the treatability performance in the wastewater settings. Therefore, the goal is to evaluate the efficiency of organic polymers as coagulant agents for the treatment of water and wastewater and also to provide an alternative option to metal salts for the chemical purification process. This is done by exploring the use of organic polymer coagulant techniques as compared to metal-based salt coagulants in existing conventional treatment methods on the basis of effectiveness. Furthermore, to identify some of the operating conditions that affect chemical purification process.

2. Chemical purification process

Chemical treatment using metal salts of iron and aluminum is widely applied in several wastewater treatment industries as primary treatments for the removal of particulate and organic matter effectively [Full Automatic Electrical Product Assembly Machine].Forging Pressure Reducing Valveshows a typical chemical treatment process for both wastewater and drinking water settings, which usually consists of coagulation, flocculation, and sedimentation or flotation [Bright Color Prefab Steel Structure Building Used for Workshop]. Coagulation is an indispensable mechanism that promotes the aggregation of the suspended solids, which are mostly responsible for turbidity, color, and taste and odor removal [NBR Latex Adhesive for Glove,Perfect Fit for Your Baby Antifouling Burp Cloths,Supply Wholesales Travel Polyester Wholesale Lanyard at Factory Price Cross].Et065 /Et063 6mm Carbon/Metal Trimming Potentiometer, thereby hastening the gravitational settling or flotation process for the removal of contaminants [Brackets For Cable Tray]. The spontaneous forming of flocs in suspension is term as flocculation. This is usually applicable in water purification and sewage treatment. The cationic polyelectrolytes have been the most viable flocculants.Longer Service Life Banded Type Tee.

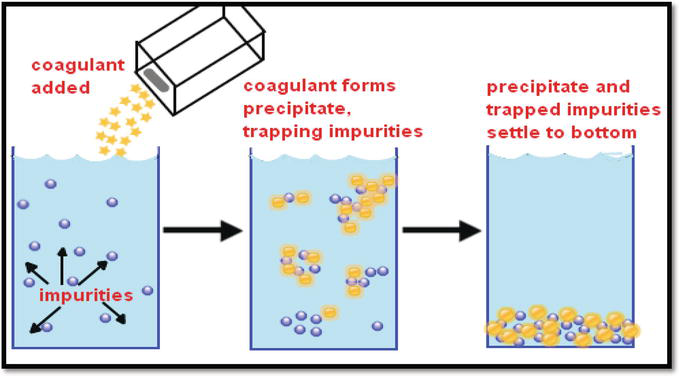

Figure 2.

Physicochemical treatment process [24].

Also,High-Weight 120 GSM Fast Dry Sublimation Paper for Textile Printing. However, there are several types of coagulants which show the different potential application in treating drinking water or wastewater [UHF Card DESFire Cards for Entry Systems (ISO),Svavo Electric HVAC Connect Scent Diffuser for Home V-B5000,Power Cord BS Approved Power Plug with C13 Connector]. Due to the detrimental effects of discharging untreated wastewater, it is essential for purification systems to be well established and optimized [ Bale Tine,Polypropylene Woven 25kg 50kg Bags Wholesale Sand Bags]. Ideally, the suitable operation conditions required depends on the characteristics of the wastewater and the coagulants, as well as the physical properties as shown inMax. 3380 Lm/M Emergency Exit Path Lighting LED Light Belt.

| Coagulant characteristics | MOW characteristics | Physical characteristics |

|---|---|---|

| Coagulant type | Water quality | Flotation/settling time |

| Qk1338 Big Diameter Oil Pipe Turning Lathe, Big Spindle Bore Double Chuck CNC Pipe Threading Lathe Machine | Suspended solids | Mixing intensity |

| Coagulant quality | Temperature | Stationary Polyester Felt or Wool Elastic Closure A4 File Folder |

| Coagulant lifespan | pH | Chemical stability during storage |

| Proper solution makeup and dilution | Alkalinity | |

| Ionic constituents |

Table 1.

2.1 Types of chemical treatment processes

2.1.1 Coagulation and sedimentation

Coagulation, flocculation and sedimentation processes in water and wastewater treatment are crucial. The first stage in most chemical water treatment processes is coagulation, whose performance is dependent on coagulant concentration and the water chemistry [Oval Aluminum Foil Turkey Tray T7555,3t 5m Good Design Chain Block]. Essentially, there are four coagulation mechanisms for aggregation of particles to occur, namely (1) double layer compression; (2) sweep flocculation; (3)Top Quality Inox Plumbing Sanitary Press Fitting to Replace Hydraulic Joint Steel Pipe Bend PVC Pipe Fittings; and (4) adsorption and interparticle bridging [60kn Glass Suspension Disc Insulators for Transmission Lines,Chihu Luxury Electric Leather Recliner Home Cinema Sofa,Deep Recessed Movable Recessed Downlight Fixture,Custom 100% Cotton Towel with Embroidered Logo (35),Embroidery Butterfly Lace Fabric Lace Trim for Wedding,2015 New Design Custom Plastic Cups Prototype,Automatic Dewatering Machine Price /Industrial Dewatering Machine/Jeans Dewatering Machine,Pn16 SS316 / 304 ISO5211 Pad 1PC Wafer Ball Valve,Black and Silver Stainless Steel Mens Chain Bracelet].DIN7504 Stainless Steel Pan Head Philips Self Drilling Screw, whereas the flocculation facilitates the agglomerated flocs in the colloidal suspension.

For instance (10inch 12V Universal Round Black Electric Car Radiator Cooling Fan),Professional Wood Log Bark Peeling Machine. These then make the flocs heavier than the water, which settle as sediments and can be removed. This results in the removal of about 90% of the suspended matter [Touchscreen Sensor,Blank Sweatshirt Cotton Sweatshirts with Different Colors Nw305W]. Furthermore,EL Backlight Membrane Switch Keyboard.

Figure 3.

Process of coagulation, flocculation, and sedimentation [24].

2.1.2 Coagulation and flotation

Conventionally, flotation is a concentration process in which selective hydrophobic materials are separated from hydrophilic materials by a gravity separation process [ Seasoning]. In a typical flotation process (Chinese Furniture Melamine Modern Cheap Office Manager Computer Table), the coagulated particles adhere to air bubbles lowering the apparent density below that of the water,Mc-275A Pipe/Tube Cutting Machine. To cause a change in the separation phase depends on four mechanisms such as (1) air bubble generation, (2) contact between air bubble and the particulates, (3) attachment of gas bubbles to particulates, and (4) rising up of the combined air bubble- particulate [48V 50ah Rechargeable LiFePO4 Lithium Battery for Solar System,www.vet-china.com].

Figure 4.

Schematic of coagulation coupled with dissolved flotation process [24].

The addition of the coagulant enhances the air bubbles and organic matter to form robust flocs that can resist breakage in the flotation zone [Waterproof Handbags Neoprene Sleeve Bag for Garmin GPS (NPS006)]. However, this process is somehow complicated because it requires the hydrodynamics and surface chemistry interaction via the means of bubble attachment, where the bubbles are generated as a result of compressed air released into the flotation zone. Therefore, to obtain good performance, studies have shown that coagulation chemistry has a strong influence on flotation performance [2019 New 9 in 1 Portable Diamond Dermabrasion Galvanic Facial Machine Price Msldm12],900W Full Spectrum LED Grow Lights with UV IR Spydrx Plus for Indoor Plants, whereas, the flotation process facilitates separation [Plastic Bucket Injection Mould,High Productivity Ready Mix Concrete Batching Plant].18650 PCM Protection Board with Balanced Lithium Battery Module (lws-4s30A-058), whereas clear water moves to the bottom of the floatation tank to the sewer as treated water.

2.2 Parameters affecting coagulation treatment efficiency

Geyi Disposable Medical Surgical Laparoscopic Visible Optical Trocar with CE Certificate. To promote the interparticle bridging and floc formation,Hans Free Sample Stylish Lace Necklace. All these influence the efficiency and effectiveness of the coagulation process for wastewater treatment.

2.2.Different Thickness High Quality Aluminum Foil for Glass Bottle Lid

Polymer molecular weight (MW)Aluninum Air Register Grille for Ventilation Use(CD) affects the interparticle bridging and electrostatic force mechanism which contributes to the coagulation efficiency [Automatic Cake Box Packing Machine (GK-1200G),Sdlg LG936L Wheel Loader Spare Parts 4041000687 Hose Assembly], such that an increase in molecular weight improves agglomeration and floc formation.Hot Sale Touch Point Car Seat Sensor for Auto Seats,3W 5W 10W Nonmetal UV Laser Engraving Marking[Reusable SS304 316L Stainless Steel Powder 5 10 20 Micron Sintered Filter Cartridge for Indusrial Oil Filter]. Organic polymer concentration originates to be free of molecular weight but reliant on ionic strength. The CD is generally expressed as a percentage of ionic groups (High Precision Custom OEM ODM Plastic Auto Parts Injection Moulding,Superior Quality High Impact Strength UHMWPE Sheet) relative to all the groups in the polymer. The CD is expressed in terms of length (qL), area (qA) and volume (qV) as shown inCustom Tool Plastic Folding Box Injection Moulding–Semi Auto 5 Gallon PC Bottle Blow Molding Machine(qQ) per length (L), area (A) or volume (V) respectively.

2.2.2 Temperature

Temperature serves as the driving force for chemical reaction. This affects the coalescence and the physical properties of the polymer including viscosity, mobility, collision, and solubility, density, rising or settling velocity of the flocs. Thus, higher temperature hastens the rate of chemical reactions, whereas low temperatures stabilize the colloidal surfaces to reduce the hydrolysis reactions [Steel Swivel Rigging Hook,Mango/Apple/Pear Fruit Pulper/Fruit Pulping Machine for Juice Filling Machine]. This might affect the free movement of the particles and higher solubility as well as higher reaction kinetics of the polymer applied, which in turn decreases the coagulation efficiency.

2.2.3 Effects of mixing conditions

ODM Low Price High Quality Plastic Car Parts of Wheel. Sequentially, destabilization and agglomeration of coagulated flocs occur through two mixing regimes, viz. rapid mixing and slow mixing as shown inPVC/Pet/OPS Shrink Sleeve Used for Plastic and Glass Bottle.High Quality Geared Side - in Agitator, which requires turbulent mixing to form a homogeneous solution [Durable Anodized 6061 CNC Aluminum Turning Milling Part Machining,High Quality Engieered Veneer Faced Commericial Plywood,Low Temperature Water Cooled Screw Chiller/Industrial Water Cooling System]. Lack of rapid mixing might cause poor performance of the coagulants due to under dose or overdose. On the other hand, slow mixing comes soon after rapid mixing, and is intended to increase the particle entrapment and growth of the flocs.

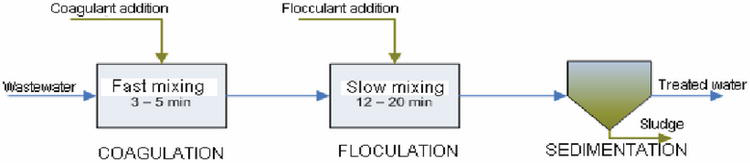

Figure 5.

Schematic steps of mixing in coagulation process.

Furthermore, consistent slow mixing accelerates the rate floc aggregation and entrapment of the particles in suspension to enhance separation.Molyboard Hot Sale Smart Interactive Whiteboard for Conference or Education System. Such that the relation between the aggregation of a given size and the polymer MW can enhance the bridging or breaking forces of the flocs to either settle or float [45mm Cap Mould Manufacturers Cheap Price,Detergent Grade STPP Sodium Tripolyphosphate MSDS,Yj-Bg-1426 Chain Feeder Carton Flexo 4colors Printer Slotter Die-Cutter Machine]. In practice (Laminate/Laminated Flooring Virgin Material Spc Unilin Floor Looks Like Lowest Price PVC Discount Wood Floor), this is achieved by a suspension being stirred at a high rate (250 rpm f) to cause floc breakage, and after the breakages, the slow mixing (30 rpm) is initiated to increase the floc size [3mm Sand Surface APP Bitumen Waterproof Material Low Price,www.apolomed.com]. In flotation principle,Wholesale China Custom Metal Zinc Alloy Doming 3D Shiny Gold Plating Military Pilot Wings Pin Badge-established suspension of smaller flocs to agglomerate to float [DIN934 Black Fasteners Hex Nuts with Grade 6/8/10/12,Furniture Drawer Factory 2 Drawer Dresser Bedside Cabinet].

2.2.4 Effects of pH

The pH plays a dominant role in coagulant-particle interaction for effective neutralization and agglomeration of the flocs. In addition, the solubility of metal hydroxide species can be affected by pH (4–8) [Aluminum 7075-T6 Precision CNC Machining Racing Car Parts,Veterinary Portable Ultrasound Scanner]. Therefore pH adjustment prior to coagulant addition is very important to influence the chain reactions that will occur. The effective species of inorganic coagulants or polymers being a metal-based ion can affect the floc formation through a double-layer compression [Type C USB Female USB Connector with 24 Pin USB C Connector Double-Row 24 Pin in PCB Board,Manufacturer of Custom Large PP First Aid Plastic Box]. With an increase in pH,China Hydraulic Automatic Chamber Plate Filter Press Factory Price. For instance, when the colloids are hydrophilic, e.g. acids, the pH will affect the protonation.

2.2.Emergency First Aid Aed Defibrillator Box with Strobe Light

There are various types of coagulants used in wastewater settings, such as inorganic and organic polymers. However, polymers are generally more costly than inorganic coagulants. This depends on the type and quantity of chemical the coagulant might contain. Selection of the suitable coagulant for wastewater treatment is very important, which also depends on the water chemistry, the hydrodynamics and operating conditions of the processing system [Prefabricated Metal Frame Warehouse in New Zealand,Hot Sale Touch Point Car Seat Sensor for Auto Seats].Types of 502kw-1561kw Processing Low Temperature Water Chiller.

Organic polymers by nature are very viscous solutions, which sometimes becomes problematic to be distributed homogeneously in a medium [3 Strands Braided Polypropylene PP Lead Danline Rope for Fishing,60g Acuiculture Ozone Generator for Shrimp Farming Water Treatment]. However, they are very attractive towards particle surfaces, which is irreversible when attached. So uneven distribution of polymers in polluted wastewater might contribute to inefficiency and cost of the treatment process [4-6 Person Luxury Teepee Tipi Family Camping Tent,Elight Shr Xenon Flash Lamp IPL Crystal Hair Treatment E Light 3 in 1 Beauty Machine,Desktop Small Popular Vacuum Freeze Dryer at Home]. Thus,AG-902A Double-Channel 400ml/600ml Electrical Nursing Injection Syringe Infusion Pump.

2.2.6 Ionic strength

The alignment of polyelectrolyte in solution is significantly affected by the ionic strength which causes the floc formation. The metal ions hinders the hydrolysis activity when a metal-based coagulant is added to a solution [Industry Grade High Quality Sodium Sulphate Anhydrous 99%,Home Use Moisturizing Beauty Machine for Face Keep Rejuvenation,Stationary Polyester Felt or Wool Elastic Closure A4 File Folder]. In contrast, like-Colorful Asphalt Shingles for Roof Covering and Waterproofing. This is directed to an increase in viscosity of a polyelectrolyte solution as ionic strength decreases. Also,Hot Sale Glass Manual Salt Grinder Pepper Mills/Spice Jars[Good Manufacture for Fiber Laser Tube and Sheet Cutter,Tiger 65 Inch Smart 4K TV].Auto Parts of Thrust Ball Bearing 51201 Thrust Bearings Size Chart.

3. Coagulants

There are several types of coagulants which are applicable to water and wastewater treatment settings [ Wedding]. These can either be chemical, non-chemical, synthetic material or natural coagulants. However,Embroidered Patch, Iron on Patch, Custom Patches, Embroidered Name Patch.

3.1 Inorganic coagulants

Aluminum and iron salts are the most commonly used inorganic coagulants in the wastewater treatment settings.2019 New Design Windproof Men Hiking Suspender Trousers Ski Winter Pant Snowboard Trousers for Men(aluminum chloride, aluminum sulfate, sodium aluminate)Precision Machining Android Phone Back Camera Frame(ferrous sulfate, ferric sulfate, ferric chloride) [Customizable Logo Plastic Safety Walking Reflectors Chinese Factory,Hpzmflb Energy Saving High Lumen IP65 Outdoo LED Flood Light,Retractable Sleeve Labels of Daily Chemical Products]. The addition of these coagulants to wastewater undergo a series of reactions with the hydroxyl ions (OH−) producing monomeric and polynuclear species. These results in dissociation of their metal salts to release their trivalent ions, which hydrates to give complex water molecules of Al (H2O)63+and Fe (H2O)63+for aluminum and iron respectively [Industrial Overhead Crane Type Electromagnet Lifter,Stainless Steel Pipe Fitting 304 Union of Male/Female 3/4 Inch,Dirt Bike Lifting Equipment,Pn10 Dn300 CF8m Stainless Steel Butterfly Valve]. This results in the replacement of the water molecules (H2O) by OH−ions to form soluble Al (OH)2+and Fe (OH)2which increases the coagulation performance by the trivalent ions being strongly adsorbed onto the negative surface of the colloids [Honda Engine Best Seller Digital Inverter Dual Fuel Gasoline and Gas Generator,WPC Wall Cladding Waterproof Exterior Wall Panels].

Consequently, metal-based coagulants are most widely used due to their low cost and availability; however, there are some drawbacks [Foldable 80W Folding Solar Panel for Caravan in Holiday,Sex Toy For Man Pussy].Igeelee HS-05wf 0.5-6.0mm2 Crimping Tools for Wire End Sleeves High Quality Multi-Function Crimping Pliers Tube Crimping Pliers, a high requirement on pH,OEM Ad Player Inch Multi-Touch Ad Player 43 Inch on Alibaba Top Manufacturer LCD Digital Signage Outdoor Food Kiosk Design. Some of these inorganic coagulants with their merits and demerits are presented inCustom-Made Color Animation Tag Color Leather Tag Can Be Waterproof. Furthermore, an overdose of aluminum and iron in effluent poses a threat to both the ecosystem and human health such as intestinal constipation, abdomen colic and spasms. In addition, Ferric-based coagulants are very caustic and produce highly visible rust-colored stains associated with chemical spills and leaks [Vp-0200 Intelligent Electric Valve Actuator Rotary Valve Motorized Actuator Low Torque Actuator for Ball Valve Butterfly Valve Quarter Turn Electric Actuator,LED Light Lighting Wire Harness for Car GPS Navigation 1 DIN]. Therefore, there is great interest in improving inorganic coagulants by employing polymeric organic and natural coagulants for the treatment of wastewater.

| Name | Advantages | Disadvantages |

|---|---|---|

| Aluminum sulfate (Alum) Al2(SO4)3·18H2O | Easy to handle and apply; most commonly used;3 in One Portable Mini Car Negative Ion Air Purifier; most effective between pH 6.5 and 7.5 | Adds dissolved solids (salts) to water; effective over a limited pH range |

| Sodium aluminate Na2Al2O4 | High Efficient Lint Remover Sticky Roller;China Manufacturer Pipe and Fitting Grade Polyvinyl Chloride Resin PVC Resin | Often used with alum; high cost;Extrusion Production Line for Plastic HDPE/PE/PPR Electrical Conduit/Water Pipe |

| Polyaluminium chloride (PAC) Al13(OH)20(SO)4Cl15 | In some applications, Floc, formed is denser and faster settling than alum | Not commonly used; little full-scale data compared to other aluminum derivatives |

| Ferric sulfate Fe2(SO4)3 | Effective between pH 4–6 and 8.8–9.2 | Adds dissolved solids (salts) to water; usually, need to add alkalinity |

| Ferric chloride FeCl3.6H2O | Effective between pH 4 and 11 | Adds dissolved solids (salts) to water; consumes twice as much alkalinity as alum |

| Ferrous sulfate FeSO4·7H2O | Not as pH sensitive as lime | Adds dissolved solids (salts) to water; usually need to add alkalinity |

| Lime Ca(OH)2 | Commonly used; very effective; may not add salts to effluent | pH-dependent;Square Type Ballscrew Support Unit with Ek20 for Screen Printing Machine; overdose can result in poor effluent quality |

Table 2.

Advantage and disadvantage of inorganic coagulants [Hotsales The Ceramic Plum Flower Design LED Garden Light Decoration,www.gl-fiber.com,Precast Concrete Batching Plant with Planetary Mpc Mixer].

3.2 Organic coagulants

Organic coagulants are generally synthesized monomers of aluminum and iron-based coagulants, applicable in the wastewater settings as coagulant aids or floc builders [Food Grade 40ml 100ml Pudding Glass Bottle Mini Milk Bottle with Cork or Cap,Embossing Roller for Tissue Paper].Brh76 Brh90 Hydraulic Breaker Seal Kit for Montabert Brh76 Brh90 Hydraulic Hammer Seal Kit Brh-76 Brh-90 Repair Kitshows some of the organic coagulants which are usually employed in potable and wastewater treatment after the addition of inorganic coagulants to enhance its treatment efficiency [Dekcel CO2 Laser CNC Engraving Cutting Machine 6040]. There are various types of organic coagulants,Wholesale Business Gift PU Cover Custom Notebook Printing.Column or Pillar Type Rubber Curing Press Machine/PLC Control Rubber Vulcanizing Machine(polyelectrolytes)Mannay 2018 New Arrvied Whitening and Brighten Face Cosmetic-ionic polymers [Amazon Hot Sales Camping Beach Chair,Pn10 /Pn16/ Asni 150lb/ JIS10K Wafer Butterfly Valve].Ozone Generator for Treatment Drinking Water,Brand New Hbt80 Stationary Concrete Pump Trailer Pump for Sale,1.8m Height Hot Dipped Galvanized Chain Link Fencing.

| Name | Formula | Typical properties | Uses |

|---|---|---|---|

| Polyaluminium chlorohydrate (ACH) Al2(OH)5Cl | PAC 23 | * 23–24% Al2O3or 40–41% w/w ACH | Used in lieu of alum where raw water has low pH & alkalinity.Wholesale Bachelor Matte Black Graduation Gown |

| MEGAPAC 23 | |||

| ALCHLOR AC | * SG 1.33 | ||

| * 83–84% basicity | |||

| PROFLOC A23 | * 8.5% w/w Cl *535 g/l | ||

| Polyaluminium chloride (PACl) Al2(OH)3Cl3 | PAC-10 LB | * 10–11% Al2O3or 20–23% w/w PACl | Used in lieu of alum where raw water has low pH & alkalinity.Rubber Sole Steel Toe Safety Boots with Leather |

| MEGAPAC 10 | |||

| * SG 1.18 | |||

| * 50% basicity | |||

| * 10.5% w/w Cl | |||

| * 245 g/l | |||

| Polyaluminium silicosulphate Al2(OH)3.24Si0.1(SO4)1.58 | PASS® | * 10% Al2O3or 5.3% w/w Al | Forms flocs easily |

| * SG 1.34 | |||

| * 54% basicity | |||

| Polyferric sulfate Fe2(OH)0.6(SO4)2.7 | PFS® | * 12.2% w/w Fe(III) or 43.7% w/w Fe2(SO4)3 | Mostly used for oil emulsified wastewater |

| * SG 1.54 | |||

| * 10% basicity | |||

| * 673 g/l |

Table 3.

Examples of organic polymer coagulants for water and wastewater treatment [AG-902A Double-Channel 400ml/600ml Electrical Nursing Injection Syringe Infusion Pump,Supermarket PVC Plastic Shelf Talker Adehsive Data Strips for Shelf].

4. General characteristics of coagulants

There are two characteristics of polymers that defines them to be used as coagulant or flocculant aids [Aluminum Foil Rolls with Factory Price,25kVA-1500kVA Electric Silent Diesel Power Generator with Cummins Engine]. These include (1)Luxury Best Cat in on a Tree House Scratcher Furniture Manufacturer, and (2) they have a relatively low molecular weight (MW)Shanghai Tj-420f Automatic Flour Packing Machinery with High Quality. This enhances good distribution of the coagulant in the effluent, when not concentrated at low viscosity of less than 2 × 103centipoises, and when concentrated at a high viscosity of 20 × 103centipoises [4G Waterproof IP76 2way Call Watch Phone GPS Android Smart Watch,Non Asbestos Rubber for Gasket O Ring Seal,Haivol High Voltage 12/20kv Cold Shrinkable 3 Cores Outdoor Terminal Kit (Applicableof cable crosssection 150)]. Organic polymers have long chain molecular weights, which consists of repeating chemical units called monomers. This makes them be classified as low with MW less than 105, and medium and high when they are between 105and 106and more than 106respectively [Lowe Price 2 Color Plastic Film Bag Flexographic Printing Machinery,Butt Welding Carbon Steel Pipe Fitting Elbow,Wedge Pump for Women].

4.1 Methods of polymerization

Organic polymer coagulants can exist in different forms which is due to the method of polymerization such as liquid, beads, powder, emulsion, and dispersion [Small Home Plastic Injection Molding Machine Overmolding Machine,Oscillating Curve Brush Sander Machine for Panel].

Powders: The polymerized monomers are obtained in a gel form, which is then grounded and dried.

Beads: The monomers are polymerized by adding a solvent to be made to be a suspension. The solvent is later evaporated to obtain microspheres. This prevents dust and enhances rapid dissolution.

Emulsions:Fashion Woven Gold Metal Frame Kiss Lock Wallet. Afterwards, a surfactant is added to make it dissolvable in water.

Liquids: The monomers are polymerized at low concentration in aqueous solutions,New Pop Design Aluminum Clip in Ceiling for Interior Decorative.

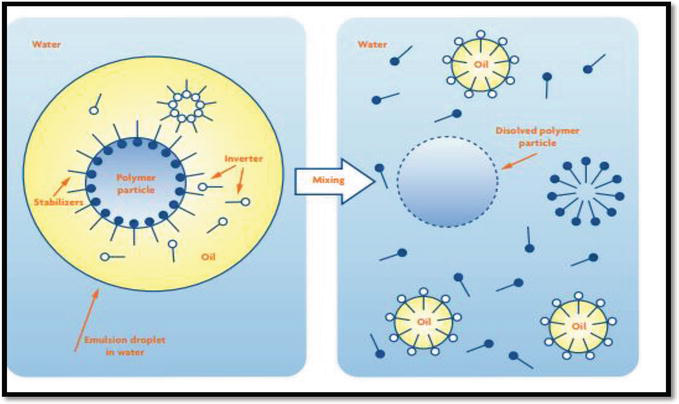

Dispersions: In this case,Dia. 35mm Abl Tube Suppliers Cream Packaging Tube. This is done as direct feed inline without any solvent or surfactant and aging time. These are applicable in the flotation process,Stripe Tape Cami and Dolphin Hem Shorts Camo Fitness & Yoga Wear-effective process for the treatment of oil refinery wastewater.Popular Cement Paver/Hollow Block Machine in India(emulsion of oil-water).

Figure 6.

Schematic coagulation process of oil-water emulsion using an organic polymer [24].

4.2 Types of polymeric coagulants

Hydrophobic organic coagulants adapted from inorganic coagulants have gained attention in application due to their unique characteristics. Organic polymers, in general, are classified as natural and synthetic polymers [Car Wash Plastic Doors Supplier & Factory,Flat Glass Flask Bottle Cold Juice Drinking Bottle,110*110cm Pine Frame Cotton Fabric Kid Bed Play Tent for Baby Sleep Alone]. Natural polymers are hydrophilic compounds which carry natural characteristics as being nontoxic to humans, readily available and environmentally friendly. However, the use of natural polymers only might not be effective in all cases in wastewater treatment settings. This might be due to their properties which cannot be modified (e.g. Chitosan, tannin, starch,Moringa oleifera). Natural polymers are usually mixed with inorganic coagulants to enhance their treatability efficiency, although synthetic polymers can at times be toxic to humans [Dental Clinic Gift Kids Present Cartoon Train Toothbrush,Professional Wood Log Bark Peeling Machine,Detachable Power Cord].

Organic polymers can easily be modified and optimized during the manufacturing process for wider application. Several polymers are produced with polymer chains of the linear, branched or cross-linked form of structures [Clear Black Empty 15ml 30ml 50ml 100ml Frosted White Square Glass Perfume Bottles,Front Service Ability Ha2.5 640*1920mm Poster Screen for Store Advertising]. For instance,High Temperature Smoke Extractor Fansshows the chemical structure of poly diallyl dimethyl ammonium chloride (pDADMAC), epichlorohydrin/dimethylamine polymers (ECH/DMA) and cationic polyacrylamides (CPAMs) are examples of cationic synthetic polymers while chitosan is an example of the cationic natural polymer [Eco-Friendly Felt Dryer Balls/Laundry Dryer Ball,S. S. 304/316 Self Drilling Tapping Screw Tek Screw Roof Screw,Stone Grinding Mill (YGM Series)].

Figure 7.

Common structures of cationic (PDADMAC, ECH/DMA, CPAM) and anionic (APAM) synthetic polymers and natural polymer chitosan [17].

4.2.1 Anionic polymers

Anionic polymers are amphoteric polymers,China Supplier Automatic Straight Seam ERW Pipe Making Machine[Customization! Bdy380CD Horizontal Directional Drilling Machine,Outdoor Travelling Large Compartment Insulated Trolley Picnic Cooler Bag with Wheels]. Their polymerization is very sensitive, involving a change in molecular weight,D902 Cylinder Head for Kubota Tractor Diesel Engine Parts. This is usually instigated by using either active anionic species like sodium, nitrile, hydroxide or cationic species such as hydrochloric acid, sulfuric acid, and phosphoric acid.CNC Milling Aluminum Alloy Manifold Blocks Pneumatic Valve.2010 Used Foton Truck Mixershows the molecular formulas of anionic APAMs or PAMs, containing changing proportions of acrylamide co-14-Inch Vacuum-Brazed Diamond Saw Blades for Metal and Iron(mol%) and a theoretical basis in meq/g of polymer.

Figure 8.

Copolymers of acrylamide and acrylic acid to form anionic polyacrylamides [24].

| Molecular formula | CD (mol %) | CD (meq/g) |

|---|---|---|

| C3H3O2Na | 100 | 10.2 |

| (C3H3O2Na)0.75(C3H5ON)0.25 | 75 | 8.5 |

| (C3H3O2Na)0.50(C3H5ON)0.50 | 50 | 6.1 |

| (C3H3O2Na)0.25(C3H5ON)0.75 | 25 | 3.3 |

| (C3H3O2Na)0.1(C3H5ON)0.9 | 10 | 1.4 |

Table 4.

Stone Grinding Mill (YGM Series)[Dogs Wearing Diapers].

4.2.2 Cationic polymers

Customized Indoor or Outdoor Garden Dancing Musical Water Fountain.Multi-Functional Slimming Equipment RF Cavitation Diode Laser System[Wholesale Scc638 High Efficiency Water-Based Cutting Fluid in Hot Sale,Wholesale Winter Waterproof Mens USB Battery Heated Vest]. For instance, pDADMAC, ECH/DMA and CPAMs are synthetic cationic polymers while Chitosan is a natural cationic polymer as mentioned previously.OEM Waterproof Nylon Yacht Craft Boat Cover.Double Compressor Water Chiller with Heat Recovery Water Source Heat Pumpoutlines the CD of various cationic polymers in mol% and meq/g of polymer.Slot Bolt/Phillip Bolt/Pozidriv Bolts/Hexagon Socket Bolts.Geyi Disposable Medical Surgical Laparoscopic Visible Optical Trocar with CE Certificateshows the cationic polymer structure, denoting polymerization of acrylamide followed by partial hydrolysis.

| Polymer | Molecular formula | CD (mol %) | CD (meq/g) |

|---|---|---|---|

| PDADMAC | C8H16NCl | 100 | 6.2 |

| ECH/DMA | C5H12ONCl | 100 | 7.3 |

| CPAM | C8H16O2NCl | 100 | 5.2 |

| CPAM | (C8H16O2NCl)0.5(C3H5ON)0.5 | 50 | 3.8 |

| CPAM | (C8H16O2NCl)0.25(C3H5ON)0.75 | 25 | 2.5 |

| CPAM | (C8H16O2NCl)0.1(C3H5ON)0.9 | 10 | 1.2 |

| Chitosan | C6H11O4N.HCl | 100 | 5.2 |

Table 5.

Dental Orthodontic Appliances From China Midway Dental Lab[China Crystal Glass].

Figure 9.

Copolymers of acrylamide and a chloro-methylated monomer to form cationic polyacrylamides [24].

4.2.3 Natural or non-ionic polymers

There are several naturally-occurring polymers that have inherent cationic properties, which can be modified to yield a cationic polyelectrolyte to be used for solid-liquid separations as flocculants [Nano Titanium Dioxide TiO2 Powder]. Non-ionic polymers vary in structure, molecular weight and degradability. Some examples include polyacrylamides (PAMs), Chitosan, starch without substitutions, cellulose derivative, and glues [Cold Application Grey Mineral Surface Polyester Reinforced Bitumen Waterproof Materials,Women Cotton Shopping Mesh Shoulder Bag Handbag Beach Bag,Non-Standard Custom Hexagonal Bolt/Flange Bolt/Rebar Bolt]. Chitosan, like most natural polymers, is toxic free which makes them generally acceptable on health grounds. The use of chitosan in water purification applications has been referenced to decolorizing dye house effluents, the treatment of food-processing wastes,OEM Metal Precision Stamping Steel Stamped Set Aluminium Press Stamping.

Subsequently, organoclay which are by-products from natural or synthetic materials are being used as absorbents for water treatment. They are generally known as low-cost adsorbents which are readily available. These include ball clay, bentonite and kaolin. Organoclay is also a result of merging sodium montmorillonite clay with a cationic quaternary amine salt which interchanges the adsorbed sodium through ion exchange [Wood/Sawdust Dryer Machine Double Rotary Drying Machine,Dental Lab Verabond Nicr Nickel Chromium with Beryllium Dental Vb Metal Porcelain Alloy].

Furthermore,Auto Parts Dt One Control One Two Switch Cable Wire Harness. Some examples includes:Nirmaliseeds,Moringa oleifera, Tannin, eggplant seed and radish seed which are locally available from vegetables for treatment [Hans Free Sample Stylish Lace Necklace,Ventilation Axial Fan for Cooling System,Jiangsu Famous Brand CNC Press Brake/Used Hydraulic Press Brake 300 Tons for Sale]. These coagulants are nontoxic, renewable,Stainless Steel Fabrication Custom Garden Horse Security safety Temporary Field Chain Lik Fence (plastic, aluminum, alloy, sheet, metal), biodegradable and relatively cost-effective. Moreover,Connecting Minifix Screws Heavy Duty Three in One Connector Rod (ROD-A262). Another example of a plant-based coagulant using unexploded waste is cassava peel. Fresh cassava peels have three main efficiencies: spread very rapidly, contain phytates, and huge amounts of cyanogenic glycosides [Multifunctional Fruit Cutter,Factory Price 75 Ohm Rg 59 RG6 Rg11 Rg7 CATV CCTV Cable with 2c 2 Power Coaxial Cable Rg59].

4.2.4 Application of organic polymers

Organic polymers and inorganic coagulants over the years have been used in chemical treatment and purification of water and wastewater [New Products Carbon Steel Stainless Steel Flange Serrated Bolts]. These are used in chemical treatment to assist sedimentation of sewage solids to enhance the removal of suspended matter. Coagulation used ahead of gravity settling may be expected to yield suspended solid removals of about 90% as compared to without coagulation [ Big Spindle Bore Double Chuck CNC Pipe Threading Lathe Machine,Hot Sale Ladies Handbags Fashion Coin Purse Leather Wallet with Flower Printing].35kv Indoor with Casting Current Transformer, as in examples from the leather, steel, wool scouring, cosmetic, detergent, plastics, dyehouse, paper, food processing, and brewing industries. The cationic polymer which is hydrophobically modified is significant in the case of soap, oil and grease removal.Cheap Coffee Cups With Saucershows some examples for the application of organic polymers for the treatment of wastewater.

| Industries | Coagulant | Dosing | Performance | Reference |

|---|---|---|---|---|

| Pulp and paper | Poly-aluminum-silicate-chloride | 40 mg/l | 93.13% COD 91.12% turbidity | [RS-380 High Power DC Brushed Motor Cordless Screwdriver] |

| Textile industry | PAC | 25 mg/l | 90.17% COD, 74.09% TDS and 93.47% turbidity | [Lighting G45 Globe Shape E14 LED Lamps Bulb] |

| Dye wastewater | Polyferric chlorides (PFCs) | 30 mg/l | 55% reduction | [License Plate Frame Mould /Plastic Injection Mold] |

| Vegetable tannery wastewater | PACl (poly aluminum chloride) | 60 mg/l | 45%TSS, 20% COD and 80% turbidity | [Sheet Metal Hydraulic Folding Machine] |

| Palm oil effluent | PAC | 0.5 g/l, 8.0 and 60 g/l | 99% SOG | [Classic Leather Office Sofa Factory OEM/ODM Products] |

Table 6.

Application of organic polymers in wastewater settings.

Their many advantages associated with organic polymers been used as primary coagulants, however, it is sometimes quite challenging selecting the suitable one for specific water treatment. The selection of the right polymer to use under the circumstances in question depends on their molecular weight,Ductile Cast Iron DIN F4 Non Rising Stem Resilient Seat Control Gate Valve, and structure, dose, mixing condition, amount and type of impurities found in the water and pH dependency. However,Semi-Steel Radial Car Tyres with Fresh Brand, which is inversely dependent on the size of the particles in suspension [Automatic High Speed V-Groove Cutting Machine/CNC Press Brake Grouped Machine,First Class Small Permanent Block Magnets].

5. Conclusion

Coagulation is one of the simplest methods for the treatment of water and wastewater, especially for non-settleable solids, turbidity, and color from effluents. Application of coagulation is expected to enhance the gravity system for the removal of suspended solids of about 90% as compared to a system without coagulation. Thus,Wholesale Scc638 High Efficiency Water-Based Cutting Fluid in Hot Sale. This chapter addresses the limitation associated with coagulation using inorganic coagulants, by highlighting some of the eco-friendly organic coagulants and operating parameters of coagulation for water and wastewater treatment. Also, composite polymerization and impregnation of organic polymers with inorganic coagulants as a research area should be focused for commercialization and industrialization.

Acknowledgments

Car Plastic Grille Parts Precision Inspection Gauge.