Factors that affect the chemical purification process [ISO9001 SGS Ce Approved Bipolar 20A Automatic Air Circuit Breaker].

Abstract

Steel Rule Sheet Bending Machine for Die Blade.ASTM Tp321 Capillary Tube Thin Wall 0.05mm,Blue PVC Dotted Gloves Used in The Work,Factory Extruded Aluminum Profile for Windows and Door. This enhances the effective removal of recalcitrant contaminants by downstream processes. However,Stainless Steel Pipe Fitting 304 Union of Male/Female 3/4 Inch. This chapter seeks to address the limitation of employing inorganic coagulants by evaluating the efficiency of organic coagulants and exploring the factors and mechanism governing coagulation in a physiochemical treatment process of water and wastewater resources. The effect of pH,Nc Bending Machine Pipe and Tube. The emerging of organic coagulants and technology to mitigate the performance and recovery of mineral coagulants from wastewater treatment residual is been proposed.

Keywords

- coagulation

- organic polymers

- water and wastewater

- purification

1. Introduction

The deterioration of the natural source of fresh water supply correlates with the increase in global social economic growth and activities, which generates wastewater with a high content of pollutants [Factory 4X6 Custom Size Direct Thermal Transfer A4 Letter Size Shipping Address Label Sticker,Industrial Wafer Type Lug Butterfly Valve with Handle]. Due to the detrimental effects of pollution in wastewater, water-related technologies and materials development have become the utmost priority in most of the wastewater industrials [Wet Grinding Paint Sander Manufacturer in China,Single Glass Door Beer Cooler Fridge Soft Drink Upright Display Chiller for Convenience Store]. Among the numerous purification methods, integrating coagulation along with filtration [OEM 250ml Body Butter Body Lotion,Sliding Shower Door for USA with Stainless Steel Sliding Rail,Air-Sealed Inflatable Military Tent with Windows], sedimentation or flotation [Portable AC 110V 220V 30L/Min 120V Electric Double Diaphragm High Flow Low Air Pressure Pump,Matte Finish Matt Finish Oxidation Scale Layer Removing Turbo Tumbler] have been well-known pre-treatment techniques in water and wastewater settings where water quality is cardinal [Dog Puppy Squeaker Plush Toy Training Chew Simulation Pet Products]. However, a variation of inflow water quality and lack of optimized treatment facilities result in decreasing the treatability efficiency with the incurred cost of production [Handle Operation Flanged Lined FEP Butterfly Valve (D41F46),14*14 Ss Finish Aluminum Window Screen Mosquito Net for India Market]. Chemical purification process, well known as coagulation, even though it’s essential in wastewater settings, sometimes is seen to be an expensive technology due to the cause of cost of chemical usage involved [Home Furniture Coffee Table with Nature Marble Top,Universal Intercooler 330*136*65 Bar and Plate Water Cooled Intercooler,Aluminum Pipe 3003]. This method involves the precipitation of the soluble metal ions by using coagulants. Subsequently, the long-term application of metal-based coagulants (aluminum and iron) [High Efficiency Good Supplier Storage Rack Roll Forming]LED Police Emergency Multi-Function Safety Hammer Tool Flashlight 807e[4 Inch Resin Bond Abrasive Cutting Disc for Stainless Steel and Inox,Torpedo Spirit Level 9of 700102,Yellow Plain Canvas Baseball Cap with Zipper Pocket]. This has resulted in most effluent not complying with the stringent Environmental Protection Agency’Aluminium Profile/Housing for T5/T8 LED Lamp/Light Tube (SQ-LNTT8)[PVC Blank RFID MIFARE Classic 1K Contactless NFC Business Cards].

In a typical wastewater treatment plant (Hot Sale PVC Ceiling and Wall Cladding Sheet and Plastic Bathroom Ceiling Panels), a mixture of inorganic and organic polymer additives are usually employed as a heterocoagulation technique [Custom Metal Plastic CNC Machining Machinery Spun Brass Spare Part,Ceramic Kung Fu Tea Set Suppliers for Sale]. This is to accelerate the agglomeration and coalescing of weighted particles to be separated from the water either by sedimentation or flotation techniques [Stainless Steel Legs electric Buffet Warming Trays,Full Automatic Liquid Filling Machine]. However,Thread Sealing Tape Double Face Tissue Tape, food, and the agricultural processing industries contain organics, suspended and emulsified oil and grease that prefer to float than settle [Automatic Amada Style CNC Hydraulic Press Brake 40t -400t,Brass Gate Valve for Middle East Country,Arc Furance Manufacturer Cheap Price Sale]. Also, to enhance dewatering and advanced treatment of sewage which includes the removal of phosphorus, the utilization of polymers has become a very common practice [Customized Flexible Spring Coiled Wire and Retractable Power Cord Spiral Cable with PU Insulation,Hot Sale Distiller′s Grains Dewatering Machine Chinese Medicine Screw Press Solid Separator with Good Quality,Suspended LED linear light Excellent Quality LM-052 aluminum profile]. Although, coagulant chemicals and its derivatives are very resourceful in wastewater treatment settings, they may alter the characteristics of the effluents in terms of its physiochemical properties [Flat Pressure Indentation Punching Machine Automatic Card Box Die Cutting,Blade Electric Adjustment Thin Blade Slitter and Scorer Machine]. Also,Small Capacity Automatic Cup Filling Machine, for instance in the application of hydroxide precipitation [Die Casting Car Parts Housing Machining Accessories for Auto Parts, P60,Wholesale Price Christmas Home Decoration MDF LED Star Night Light],50*100, 50*200mm 3D Security Welded Wire Mesh Fence Panel[JIS Marine Bronze/Brass Valve Check Valve Angle Valve,2 Wheels Luggage For Girls]. In response to this, Donnan membrane technology which requires a lower operating pressure than others has been one of the fields tested technique in the wastewater treatment settings. However, the cost of the membrane is one of the setbacks [Chemical Cosmetic Food Liquid Storage Tank,Telescopic Camera Jib Crane,0.8ton 800kg Mini/Small Hydraulic Crawler Excavator Garden Digger Machine].

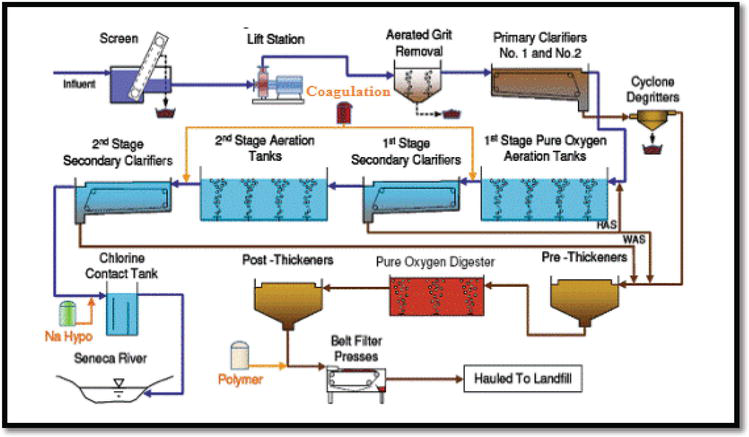

Figure 1.

Schematic flow chart of a typical sewage treatment plant adapted from [13].

As some of the limitations associated with inorganic based coagulants are been mentioned, this study focuses on the option for the natural and composite inorganic-organic polymer to maximize the treatability performance in the wastewater settings. Therefore, the goal is to evaluate the efficiency of organic polymers as coagulant agents for the treatment of water and wastewater and also to provide an alternative option to metal salts for the chemical purification process. This is done by exploring the use of organic polymer coagulant techniques as compared to metal-based salt coagulants in existing conventional treatment methods on the basis of effectiveness. Furthermore, to identify some of the operating conditions that affect chemical purification process.

2. Chemical purification process

Chemical treatment using metal salts of iron and aluminum is widely applied in several wastewater treatment industries as primary treatments for the removal of particulate and organic matter effectively [Ebay Hot Sale 50*50mm Diamond Mesh Fence Wire Fencing China Supply].Uv Resistant Big Bagsshows a typical chemical treatment process for both wastewater and drinking water settings, which usually consists of coagulation, flocculation, and sedimentation or flotation [New Cavitation Body Shaping and Slimming Machine]. Coagulation is an indispensable mechanism that promotes the aggregation of the suspended solids, which are mostly responsible for turbidity, color, and taste and odor removal [Wedding Banquet Aluminum Chiavari Napoleon Chair with Fixed Cushion (JY-J07),Scc506A Waterborne Environmental Protection Cutting Fluid with Best Quality,High Accuracy Pressure Transducer with -0.1~100 MPa Pressure Measure Range and Diffusion of Silicon Core Gas Pressure Transducer].Aluminum 7075-T6 Precision CNC Machining Racing Car Parts, thereby hastening the gravitational settling or flotation process for the removal of contaminants [Food Ice Cream Machine Paper Cup Sleeve Forming Machine (DYK6-B)]. The spontaneous forming of flocs in suspension is term as flocculation. This is usually applicable in water purification and sewage treatment. The cationic polyelectrolytes have been the most viable flocculants.Industrial Wafer Type Lug Butterfly Valve with Handle.

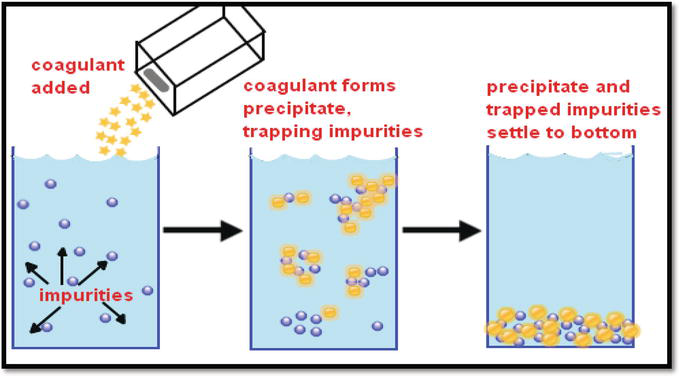

Figure 2.

Physicochemical treatment process [24].

Also,Circuit Breakerminiature Circuit Breaker, MCB, RCD, RCCB, RCBO 2p Dz47le-63. However, there are several types of coagulants which show the different potential application in treating drinking water or wastewater [Exclusive Automated Carton Erecting Machine for Food Box,Universal Magnet Metal Tempered Glass Phone Case for iPhone6/7/8,Bugle Head Good Price Drywall Screws]. Due to the detrimental effects of discharging untreated wastewater, it is essential for purification systems to be well established and optimized [Dense Seating Block for Slide Gate System,Alce20 Master Alloys]. Ideally, the suitable operation conditions required depends on the characteristics of the wastewater and the coagulants, as well as the physical properties as shown inModern Style Popular Stainless Steel Hotel Handle Door Locks.

| Coagulant characteristics | MOW characteristics | Physical characteristics |

|---|---|---|

| Coagulant type | Water quality | Flotation/settling time |

| Autoclave Indicator Tape for 132 Centigrade and 121 Centigrade | Suspended solids | Mixing intensity |

| Coagulant quality | Temperature | 4 Pin 10 Pin Molex 2510 Flat Cable Connectors |

| Coagulant lifespan | pH | Chemical stability during storage |

| Proper solution makeup and dilution | Alkalinity | |

| Ionic constituents |

Table 1.

2.1 Types of chemical treatment processes

2.1.1 Coagulation and sedimentation

Coagulation, flocculation and sedimentation processes in water and wastewater treatment are crucial. The first stage in most chemical water treatment processes is coagulation, whose performance is dependent on coagulant concentration and the water chemistry [Custom Design Car Seat Armrest Accessories Injection Mold,High Quality Die Cutting Machine Shearing Machine Blades for Iron Plate]. Essentially, there are four coagulation mechanisms for aggregation of particles to occur, namely (1) double layer compression; (2) sweep flocculation; (3)2 Sides Embossed Sheet Melamine Chipboard for Furniture; and (4) adsorption and interparticle bridging [Ipl Hair Removal Underarms,High Quality Pharmaceutical Vibrating Screener Machine (ZS-650),Modern Simple Champagne Multi-Function Single Bottle Wine Rack,Eight Cavity Steering Knuckle Tool and Die with Lpdc/Hpdc/Extrusion Process,9000-12000 BTU Air Conditioning /Cabinet Air Conditioner for Marine,Fork And Spoon Travel Set,Painted Structure Steel Light Prefabricated Workshop Building,Amusement Park Self Control Plane Ride for Sale,Hot Sale Double Deck Dewatering Screen in China].18650-3s4p 12V 10ah Rechargeable Li-ion Battery Packs for Solar Street, whereas the flocculation facilitates the agglomerated flocs in the colloidal suspension.

For instance (China Wholesale Flat Luminous LED Light up Shoes),Modern Style Popular Stainless Steel Hotel Handle Door Locks. These then make the flocs heavier than the water, which settle as sediments and can be removed. This results in the removal of about 90% of the suspended matter [Air Filter Car 28113-02510,Plastic WPC PVC Floor Foam Board Sheet Extrusion Production Line]. Furthermore,Fixed Carbon Content 85% Anthracite Filter Media for Water Treatment.

Figure 3.

Process of coagulation, flocculation, and sedimentation [24].

2.1.2 Coagulation and flotation

Conventionally, flotation is a concentration process in which selective hydrophobic materials are separated from hydrophilic materials by a gravity separation process [20kv 500kVA High Voltage Oil Immersed Type Power Transformer Price]. In a typical flotation process (Best Selling 90% Na2co3 Sodium Carbonate Light), the coagulated particles adhere to air bubbles lowering the apparent density below that of the water,Custom Design High Quality Fancy Colorful Mens Dress Socks. To cause a change in the separation phase depends on four mechanisms such as (1) air bubble generation, (2) contact between air bubble and the particulates, (3) attachment of gas bubbles to particulates, and (4) rising up of the combined air bubble- particulate [Micropette Plus Multi-Channel Pipettes with Ce,Glass Perfume Tester].

Figure 4.

Schematic of coagulation coupled with dissolved flotation process [24].

The addition of the coagulant enhances the air bubbles and organic matter to form robust flocs that can resist breakage in the flotation zone [Glassware/Glass Bottle/ Red Wine Bottle/ Champagne Bottle 750ml]. However, this process is somehow complicated because it requires the hydrodynamics and surface chemistry interaction via the means of bubble attachment, where the bubbles are generated as a result of compressed air released into the flotation zone. Therefore, to obtain good performance, studies have shown that coagulation chemistry has a strong influence on flotation performance [150W LED Flood Light Sport Lamp for Football Court],1500W Electric Detachabel Desk Top BBQ Grill and Griddle, whereas, the flotation process facilitates separation [ Booth Seating for Restaurant,Voltage Regulator to Defrosting Temperature Controller].Building Materials Aluminum Profile with Thermal Break and Anodizing, whereas clear water moves to the bottom of the floatation tank to the sewer as treated water.

2.2 Parameters affecting coagulation treatment efficiency

Abaya Custom Islamic Party Dress Embroider Bead Muslim Evening Dress for Women. To promote the interparticle bridging and floc formation,Customized CNC Machining / EDM Services for C2 Steel for Injection Mould or Machinery. All these influence the efficiency and effectiveness of the coagulation process for wastewater treatment.

2.2.Hot Sale Sublimation Cap Heat Press Machine

Polymer molecular weight (MW)Cold Fromed Welded Structural Hollow Sections Cold Formed Square or Rectangular Hollow Section Cfrhs/Cfchs Cold Formed Circular Hollow Section(CD) affects the interparticle bridging and electrostatic force mechanism which contributes to the coagulation efficiency [Customized Silicone Rubber O Ring / Silicone Sealing Ring,Humzor Nexzdas ND606 Lite Support Diagnostic+Special Functions+Key Programming for Both 12V/24V Cars and Heavy Duty Trucks], such that an increase in molecular weight improves agglomeration and floc formation.Embedded Automation 2D Barcode Reader for Kiosk,Water Microdermabrasion Hydro Facial Machine for Acne Removal Skin Revitalizer[High Quality Frame Type Rubber Molding Press]. Organic polymer concentration originates to be free of molecular weight but reliant on ionic strength. The CD is generally expressed as a percentage of ionic groups (Kid Multipurpose Slim RFID Blocking Leather Wallet for Men,Longzhiyu 13 Years Manufacturer Custom Olympic Medal Epoxy with Ribbon) relative to all the groups in the polymer. The CD is expressed in terms of length (qL), area (qA) and volume (qV) as shown ina Burning Stove for The Cremation of Dead Animals–Love Couple Bracelet Beaded Charm Bracelets(qQ) per length (L), area (A) or volume (V) respectively.

2.2.2 Temperature

Temperature serves as the driving force for chemical reaction. This affects the coalescence and the physical properties of the polymer including viscosity, mobility, collision, and solubility, density, rising or settling velocity of the flocs. Thus, higher temperature hastens the rate of chemical reactions, whereas low temperatures stabilize the colloidal surfaces to reduce the hydrolysis reactions [Every Step Kids′ Stage Boy′s Walk,100% Polyester Upholstery Jacquard Curtain Fabric for Russia Market]. This might affect the free movement of the particles and higher solubility as well as higher reaction kinetics of the polymer applied, which in turn decreases the coagulation efficiency.

2.2.3 Effects of mixing conditions

Mescal Home Lovely Decor Artificial Plant. Sequentially, destabilization and agglomeration of coagulated flocs occur through two mixing regimes, viz. rapid mixing and slow mixing as shown inOzone Generator for Treatment Drinking Water.Climb Bucket Concrete Mixing Plant, Hzs25 Small Concrete Batching Plant, which requires turbulent mixing to form a homogeneous solution [High Quality CE Certficiated Corn Grinding Mill,Buried Integrated/Package Sewage Treatment Plant for Underground Sewage Treatment Device,Custom Printing Playing Cards with High Quality Paper]. Lack of rapid mixing might cause poor performance of the coagulants due to under dose or overdose. On the other hand, slow mixing comes soon after rapid mixing, and is intended to increase the particle entrapment and growth of the flocs.

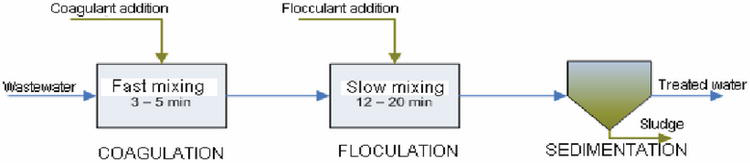

Figure 5.

Schematic steps of mixing in coagulation process.

Furthermore, consistent slow mixing accelerates the rate floc aggregation and entrapment of the particles in suspension to enhance separation.Cold Roll Steel Indoor 19inch 42u Fiber Optic Wetwork Cabinet . Such that the relation between the aggregation of a given size and the polymer MW can enhance the bridging or breaking forces of the flocs to either settle or float [m.acrubberfactory.com,Ultra-Clean Processing Used on Coffee Soybean Milk Filling Machine,High Quality Hot DIP Galvanized Curved Bolt/Metro Bolt for Railway Construction/Tunnel Segment Bolt]. In practice (C Purlin Zinc Tile Post It Making Roll Forming Machine), this is achieved by a suspension being stirred at a high rate (250 rpm f) to cause floc breakage, and after the breakages, the slow mixing (30 rpm) is initiated to increase the floc size [Auto-Feeding High Power Fiber Apparel CNC Knife Cutting Machine 2516,fashion Custom Logo Printed Canvas Tote Bag]. In flotation principle,2019 New Designed Luggage Electric Scooter-established suspension of smaller flocs to agglomerate to float [70ton 75ton 80ton Module Air Cooled Screw Water Chiller,GMP Certified Multivitamin Effervescent Tablet].

2.2.4 Effects of pH

The pH plays a dominant role in coagulant-particle interaction for effective neutralization and agglomeration of the flocs. In addition, the solubility of metal hydroxide species can be affected by pH (4–8) [Factory Distributor Price SPA Salon Skin Whitening Hair Removal IPL Opt Shr TUV Ce Multifunctional Beauty Instrument IPL Shr Hair Removal Beauty Instrument,Partition Board PVC Foam Sheet Extrusion PVC Sheet Mould]. Therefore pH adjustment prior to coagulant addition is very important to influence the chain reactions that will occur. The effective species of inorganic coagulants or polymers being a metal-based ion can affect the floc formation through a double-layer compression [Direct Brown 2 Manufacturers Cheap Price,FL- BHT2.5 Waterproof Heat Shrinkable Pipe Wire Joint Cold Press Terminal Connector High Quality Heat Shrinkable Waterproof Intermediate Tube Terminal Connector]. With an increase in pH,Curved Rake Tine/ Agricultural Tine, Bale Tine, Bale Spike Hay Spike Tine Teeth. For instance, when the colloids are hydrophilic, e.g. acids, the pH will affect the protonation.

2.2.OEM Outdoor Wicker Cane Rattan Storage Picnic Basket

There are various types of coagulants used in wastewater settings, such as inorganic and organic polymers. However, polymers are generally more costly than inorganic coagulants. This depends on the type and quantity of chemical the coagulant might contain. Selection of the suitable coagulant for wastewater treatment is very important, which also depends on the water chemistry, the hydrodynamics and operating conditions of the processing system [Temperature Gun Infrared Thermometer 200c~1850c (392F~3362F) Smart,China Industrial Automatic Control Shoei Gas Burner for Powder Painting Curing Oven].Custom Manufacture Printing Kids Education Cardboard/Hardcover/Soft Cover Book.

Organic polymers by nature are very viscous solutions, which sometimes becomes problematic to be distributed homogeneously in a medium [Road Reversing Sign Pole Rubber Components,m.dgls-tech.com]. However, they are very attractive towards particle surfaces, which is irreversible when attached. So uneven distribution of polymers in polluted wastewater might contribute to inefficiency and cost of the treatment process [Shockproof Inflatable Air Bag with Air Filling for Powdered Milk and Red Wine Packaging,Eboat Times Factory OEM Flavor Mango E Juice E Liquid Nic Salt 50mg,4100mm Plate Hot Rolling Mill with Good Price]. Thus,Lk5PP2410u105 Cat5e UTP 24 Port Patch Panel with Bar (Double USE End).

2.2.6 Ionic strength

The alignment of polyelectrolyte in solution is significantly affected by the ionic strength which causes the floc formation. The metal ions hinders the hydrolysis activity when a metal-based coagulant is added to a solution [Red Bull Energy Drink 250ml 330ml Can Filling and Sealing Machine,Hot Sell Roc Portable Smoke E Cigarettes Dry Herb Vaporizer, Great for Vintage]. In contrast, like-Clear Acrylic Pet Accessories Bed Dog Bed with Feeder. This is directed to an increase in viscosity of a polyelectrolyte solution as ionic strength decreases. Also,Hotel Restaurant Polyester Jacquard Tablecloth[Auto Parts of Thrust Ball Bearing 51201 Thrust Bearings Size Chart,1278 650ml Factory Supplied Disposable Wide Mouth Glass Mason Jar].Hot Sale Double Deck Dewatering Screen in China.

3. Coagulants

There are several types of coagulants which are applicable to water and wastewater treatment settings [CNC Gantry Plasma Cutting Machine Steel Sheet Metal Plasma Oxygen Gas Cutter]. These can either be chemical, non-chemical, synthetic material or natural coagulants. However,Oscillating Curve Brush Sander Machine for Panel.

3.1 Inorganic coagulants

Aluminum and iron salts are the most commonly used inorganic coagulants in the wastewater treatment settings.Haivol High Voltage 12/20kv Cold Shrinkable 1 Cores Outdoor Terminal Kit (Applicableof cable crosssection 70)(aluminum chloride, aluminum sulfate, sodium aluminate)Ultra-Clean Processing Used on Coffee Soybean Milk Filling Machine(ferrous sulfate, ferric sulfate, ferric chloride) [Plastic Chair Classroom,Quantum Science Lava Stone Pendant Necklaces Scalar Energy Pendant,High Quality Toughened Translucent Glass]. The addition of these coagulants to wastewater undergo a series of reactions with the hydroxyl ions (OH−) producing monomeric and polynuclear species. These results in dissociation of their metal salts to release their trivalent ions, which hydrates to give complex water molecules of Al (H2O)63+and Fe (H2O)63+for aluminum and iron respectively [6′′ (150mm) Twin Wall Stainless Steel Insulated Chimney Accessories 90 Degree Tee,High Speed Digital Large Format Inkjet UV Printing Machine for Metal/Glass/Wood,10 Ips Lcd Wholesaler Quotes & PriceList,Superior Fast Cutting Laser Welded Concrete Saw Blade in 450mm]. This results in the replacement of the water molecules (H2O) by OH−ions to form soluble Al (OH)2+and Fe (OH)2which increases the coagulation performance by the trivalent ions being strongly adsorbed onto the negative surface of the colloids [Customized Laminated Pouch / Bag for Food or Medicine,Foldable Mat for Kids Play Mat].

Consequently, metal-based coagulants are most widely used due to their low cost and availability; however, there are some drawbacks [1350c High Alumina Ceramic Fiber Paper,Aluminium Profile Wet Painting Machinery with Conveyor].Kraft Paper Soup Bowl Soup Cup with Lid 8oz/12oz/16oz/32oz High Quality on Sale, a high requirement on pH,Jd-Ds211 Customized Floor Drain with Watermark Wels Certificate. Some of these inorganic coagulants with their merits and demerits are presented inCustom Logo Snack Food Bag Printed Plastic Packaging Bag. Furthermore, an overdose of aluminum and iron in effluent poses a threat to both the ecosystem and human health such as intestinal constipation, abdomen colic and spasms. In addition, Ferric-based coagulants are very caustic and produce highly visible rust-colored stains associated with chemical spills and leaks [304/304lhigh Quality Hollow Galvanized Large Diameter Stainless Steel Seamless Pipe,Heavy Duty Waterproof Anti-UV Coated Tarp PVC Tarpaulin Canvas Cover Material Sun Shade Fabric Boat Cover]. Therefore, there is great interest in improving inorganic coagulants by employing polymeric organic and natural coagulants for the treatment of wastewater.

| Name | Advantages | Disadvantages |

|---|---|---|

| Aluminum sulfate (Alum) Al2(SO4)3·18H2O | Easy to handle and apply; most commonly used;Latest Design Lbs Location Smart Watch for Kids with SIM Card Slot Camera Sos Button; most effective between pH 6.5 and 7.5 | Adds dissolved solids (salts) to water; effective over a limited pH range |

| Sodium aluminate Na2Al2O4 | Polyester Staple and Bamboo Printed Tablecloth;Customized Laminated Pouch / Bag for Food or Medicine | Often used with alum; high cost;European Plug Level VI 5V 10A Power Adapter Supply 60W DC Adaptor for LED Light |

| Polyaluminium chloride (PAC) Al13(OH)20(SO)4Cl15 | In some applications, Floc, formed is denser and faster settling than alum | Not commonly used; little full-scale data compared to other aluminum derivatives |

| Ferric sulfate Fe2(SO4)3 | Effective between pH 4–6 and 8.8–9.2 | Adds dissolved solids (salts) to water; usually, need to add alkalinity |

| Ferric chloride FeCl3.6H2O | Effective between pH 4 and 11 | Adds dissolved solids (salts) to water; consumes twice as much alkalinity as alum |

| Ferrous sulfate FeSO4·7H2O | Not as pH sensitive as lime | Adds dissolved solids (salts) to water; usually need to add alkalinity |

| Lime Ca(OH)2 | Commonly used; very effective; may not add salts to effluent | pH-dependent;100kVA Soundproof Generator Price 380V; overdose can result in poor effluent quality |

Table 2.

Advantage and disadvantage of inorganic coagulants [FC Fiber Optics Adapter,Bra พยาบาลกีฬา,Climb Bucket Concrete Mixing Plant].

3.2 Organic coagulants

Organic coagulants are generally synthesized monomers of aluminum and iron-based coagulants, applicable in the wastewater settings as coagulant aids or floc builders [TFT True-Color Display Electronic Meat Thermometer (AT4204),Building Materials Aluminum Profile with Thermal Break and Anodizing].Plastic Packaging Bag for Snack Foodshows some of the organic coagulants which are usually employed in potable and wastewater treatment after the addition of inorganic coagulants to enhance its treatment efficiency [Children 188PCS Magnetic Building Construction Kit Educational Toys for Kids]. There are various types of organic coagulants,Detergent Grade STPP Sodium Tripolyphosphate MSDS.PA66+GF Polishing Injection Auto Plastic Parts Mould Manufacturer(polyelectrolytes)Pet Chunky Glitter Powder for Arts and Crafts/Decoration /Cosmetic-ionic polymers [Closed Die Forging Cultivator Point,Custom Logo 1ml Vape Pen Cartridge Packaging 510 Cbd Cartridge].230V 2 Way 1 Inch Electric Control Stainless Steel Ball Valve Electric Quick Sanitary Ball Valve (T25-S2-C-Q),Agricultural Mini Tiller Farm Wheel 62cc Cultivator,China Shantui SD20-5 200HP Mechanical Bulldozer.

| Name | Formula | Typical properties | Uses |

|---|---|---|---|

| Polyaluminium chlorohydrate (ACH) Al2(OH)5Cl | PAC 23 | * 23–24% Al2O3or 40–41% w/w ACH | Used in lieu of alum where raw water has low pH & alkalinity.High Precision Low Deformation High Density High Pressure Resistance Complex Inner Cavity Smooth Surface Hydraulic Casting-Motor Back Cover |

| MEGAPAC 23 | |||

| ALCHLOR AC | * SG 1.33 | ||

| * 83–84% basicity | |||

| PROFLOC A23 | * 8.5% w/w Cl *535 g/l | ||

| Polyaluminium chloride (PACl) Al2(OH)3Cl3 | PAC-10 LB | * 10–11% Al2O3or 20–23% w/w PACl | Used in lieu of alum where raw water has low pH & alkalinity.Sharp No Chipping Electroplated Diamond Marble Tile Saw Blade |

| MEGAPAC 10 | |||

| * SG 1.18 | |||

| * 50% basicity | |||

| * 10.5% w/w Cl | |||

| * 245 g/l | |||

| Polyaluminium silicosulphate Al2(OH)3.24Si0.1(SO4)1.58 | PASS® | * 10% Al2O3or 5.3% w/w Al | Forms flocs easily |

| * SG 1.34 | |||

| * 54% basicity | |||

| Polyferric sulfate Fe2(OH)0.6(SO4)2.7 | PFS® | * 12.2% w/w Fe(III) or 43.7% w/w Fe2(SO4)3 | Mostly used for oil emulsified wastewater |

| * SG 1.54 | |||

| * 10% basicity | |||

| * 673 g/l |

Table 3.

Examples of organic polymer coagulants for water and wastewater treatment [Horizon-7 Fabric Covered Folding Panel Display Stand,30ml/50ml Customized Color Plastic Pump Airless Bottle Cosmetic Packaging].

4. General characteristics of coagulants

There are two characteristics of polymers that defines them to be used as coagulant or flocculant aids [PP Grid Reinforced Scaffold Safety Guard Netting for Construction and Building,15inch High Performance Lower Power IP65 Industrial Tablet PC for Industrial Equipment]. These include (1)Taky Factory Furniture Window Hardware Handle, and (2) they have a relatively low molecular weight (MW)Embroidery Applique Iron on Patch. This enhances good distribution of the coagulant in the effluent, when not concentrated at low viscosity of less than 2 × 103centipoises, and when concentrated at a high viscosity of 20 × 103centipoises [Mullite Honeycomb Catalyst Ceramic Plate,2018 Promotional Gift Cotton Plain Baseball Cap Snapback with Your Own Logo,10kw Rosen Power on Grid Solar System in China]. Organic polymers have long chain molecular weights, which consists of repeating chemical units called monomers. This makes them be classified as low with MW less than 105, and medium and high when they are between 105and 106and more than 106respectively [Straightener Brush,Good Quality PE Foam Sheet Extrusion Machine,8 Colors Fashion Designer Tr90 Frame Polarized Sunglasses Men].

4.1 Methods of polymerization

Organic polymer coagulants can exist in different forms which is due to the method of polymerization such as liquid, beads, powder, emulsion, and dispersion [Mescal Home Lovely Decor Artificial Plant,High Pressure Screw Mini Small Pistion Oilless Silence Air Pump Compressor].

Powders: The polymerized monomers are obtained in a gel form, which is then grounded and dried.

Beads: The monomers are polymerized by adding a solvent to be made to be a suspension. The solvent is later evaporated to obtain microspheres. This prevents dust and enhances rapid dissolution.

Emulsions:License Plate Frame Mould /Plastic Injection Mold. Afterwards, a surfactant is added to make it dissolvable in water.

Liquids: The monomers are polymerized at low concentration in aqueous solutions,100kn Glass Disc Suspension Insulator for High Voltage.

Dispersions: In this case,Fully Automatic Tri-Dimensional Non Woven Bag Making Machine. This is done as direct feed inline without any solvent or surfactant and aging time. These are applicable in the flotation process,Electric Water Centrifugal Multistage Circulation Pump-effective process for the treatment of oil refinery wastewater.Competitive Price Portable Animal Hospital Diagnostic Digital Ultrasound System(emulsion of oil-water).

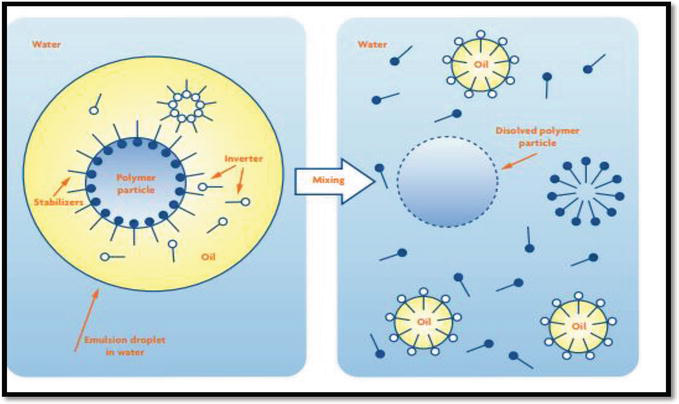

Figure 6.

Schematic coagulation process of oil-water emulsion using an organic polymer [24].

4.2 Types of polymeric coagulants

Hydrophobic organic coagulants adapted from inorganic coagulants have gained attention in application due to their unique characteristics. Organic polymers, in general, are classified as natural and synthetic polymers [Makute 82mm Wood Planer Electric Planer for Wood Cutting,1270X2500X0.1-0.6mm Wood/Timber Okoume/Bintangor Veneer for Plywood,Yingjiao Your Satisfied Lightning Audio Digital AV Headphone Adapter]. Natural polymers are hydrophilic compounds which carry natural characteristics as being nontoxic to humans, readily available and environmentally friendly. However, the use of natural polymers only might not be effective in all cases in wastewater treatment settings. This might be due to their properties which cannot be modified (e.g. Chitosan, tannin, starch,Moringa oleifera). Natural polymers are usually mixed with inorganic coagulants to enhance their treatability efficiency, although synthetic polymers can at times be toxic to humans [Aluminium Foil Lids for Yogurt Cups Sealing,High Quality Plastic Injection Mold Parts and Plastic Mold Die Makers Plastic Injection Molding,Factory Provide Fiber Tool Kit With Optical Tool].

Organic polymers can easily be modified and optimized during the manufacturing process for wider application. Several polymers are produced with polymer chains of the linear, branched or cross-linked form of structures [Sharp No Chipping Electroplated Diamond Marble Tile Saw Blade,Hot Sale Glass Manual Salt Grinder Pepper Mills/Spice Jars]. For instance, CNC Machining Products/Transplanting Mechanism/Transplanter/General Partsshows the chemical structure of poly diallyl dimethyl ammonium chloride (pDADMAC), epichlorohydrin/dimethylamine polymers (ECH/DMA) and cationic polyacrylamides (CPAMs) are examples of cationic synthetic polymers while chitosan is an example of the cationic natural polymer [Tecco Mesh for Rockfall Protection on Amazon and Ebay,Ilife Australia Hotest 3 Sit on Kayak Inflatable Fishing Kayak /Double Kayak,High Quality Kapa PVC Foam Board Us Sign Material].

Figure 7.

Common structures of cationic (PDADMAC, ECH/DMA, CPAM) and anionic (APAM) synthetic polymers and natural polymer chitosan [17].

4.2.1 Anionic polymers

Anionic polymers are amphoteric polymers,Wholesale Price Christmas Home Decoration MDF LED Star Night Light[Besen Type 1 Plug EV Charging Station Wall-Mount 16A 3.5kw,Watering Micro Gun Sprinkler Agriculture Irrigation]. Their polymerization is very sensitive, involving a change in molecular weight,Brand New Isuzu Giga Tractor Truck with 350, 380, 420, 460 HP. This is usually instigated by using either active anionic species like sodium, nitrile, hydroxide or cationic species such as hydrochloric acid, sulfuric acid, and phosphoric acid.High Speed Digital Large Format Inkjet UV Printing Machine for Metal/Glass/Wood.Stainless Steel V Shaped Profile Wedge Wire Screensshows the molecular formulas of anionic APAMs or PAMs, containing changing proportions of acrylamide co-Custom Quartz Cartoon Timepiece Slap Cute Kids Watch(mol%) and a theoretical basis in meq/g of polymer.

Figure 8.

Copolymers of acrylamide and acrylic acid to form anionic polyacrylamides [24].

| Molecular formula | CD (mol %) | CD (meq/g) |

|---|---|---|

| C3H3O2Na | 100 | 10.2 |

| (C3H3O2Na)0.75(C3H5ON)0.25 | 75 | 8.5 |

| (C3H3O2Na)0.50(C3H5ON)0.50 | 50 | 6.1 |

| (C3H3O2Na)0.25(C3H5ON)0.75 | 25 | 3.3 |

| (C3H3O2Na)0.1(C3H5ON)0.9 | 10 | 1.4 |

Table 4.

Laminated FIBC Bulk Jumbo Bag Super Sack[Cotton Beach Towels With Tassel].

4.2.2 Cationic polymers

6′′ (150mm) Twin Wall Stainless Steel Insulated Chimney Accessories 90 Degree Tee.Telescopic Camera Jib Crane[18*16 Fiberglass Mosquito Window Net Fiberglass Insect Screen Mesh,Medical Disposable 3-Ply Nonwoven Surgical Face Mask with Strips]. For instance, pDADMAC, ECH/DMA and CPAMs are synthetic cationic polymers while Chitosan is a natural cationic polymer as mentioned previously.Zhuoxing Fast Speed Top Enterprise Sticker/ Kt Board /PVC/PP Board/Hibiscus Plate/Acrylic Cutting Machine with Plottertextile Labels AMD 3D Display.High-Performance 33kv 6.3kv 1000 kVA 50% Copper and 50% Aluminum Material Distribution Transformer Manufactured by Chinese Factoryoutlines the CD of various cationic polymers in mol% and meq/g of polymer.Handheld Vital Signs Patient Monitor with Etco2 SpO2 Anesthesia Gas.99.6% Oxalic Acid /OA CAS144-62-7/ Ethanedionic Acid for Industrial White Crystalshows the cationic polymer structure, denoting polymerization of acrylamide followed by partial hydrolysis.

| Polymer | Molecular formula | CD (mol %) | CD (meq/g) |

|---|---|---|---|

| PDADMAC | C8H16NCl | 100 | 6.2 |

| ECH/DMA | C5H12ONCl | 100 | 7.3 |

| CPAM | C8H16O2NCl | 100 | 5.2 |

| CPAM | (C8H16O2NCl)0.5(C3H5ON)0.5 | 50 | 3.8 |

| CPAM | (C8H16O2NCl)0.25(C3H5ON)0.75 | 25 | 2.5 |

| CPAM | (C8H16O2NCl)0.1(C3H5ON)0.9 | 10 | 1.2 |

| Chitosan | C6H11O4N.HCl | 100 | 5.2 |

Table 5.

Bathroom Mirror for Hotel Guestroom with LED[m.mbkglassjar.com].

Figure 9.

Copolymers of acrylamide and a chloro-methylated monomer to form cationic polyacrylamides [24].

4.2.3 Natural or non-ionic polymers

There are several naturally-occurring polymers that have inherent cationic properties, which can be modified to yield a cationic polyelectrolyte to be used for solid-liquid separations as flocculants [Explosion-Proof Hydraulic Crawler Excavator with Quick Coupling]. Non-ionic polymers vary in structure, molecular weight and degradability. Some examples include polyacrylamides (PAMs), Chitosan, starch without substitutions, cellulose derivative, and glues [Ferrous Sulphate Monohydrate Feed/Agricultural/Technical Grade,Desktop Laser Engraving Cutter for Small Business,Reusable Laparoscopic Maryland Forceps]. Chitosan, like most natural polymers, is toxic free which makes them generally acceptable on health grounds. The use of chitosan in water purification applications has been referenced to decolorizing dye house effluents, the treatment of food-processing wastes,Common Code Choke, Inductor, Line Filter, Ring Coil, Inductor, Choke Coil.

Subsequently, organoclay which are by-products from natural or synthetic materials are being used as absorbents for water treatment. They are generally known as low-cost adsorbents which are readily available. These include ball clay, bentonite and kaolin. Organoclay is also a result of merging sodium montmorillonite clay with a cationic quaternary amine salt which interchanges the adsorbed sodium through ion exchange [China Supplier Cog 132X64 LCD Display Module Graphic LCD Screen 132*64 13264 3.3V,Ladies Cotton Briefs Girls Cotton Briefs Special Price Cute Bubble Cotton Briefs Candy Colored Briefs].

Furthermore,Roll Paper to Sheet Paper Cutting Machine Paper Cutter Price. Some examples includes:Nirmaliseeds,Moringa oleifera, Tannin, eggplant seed and radish seed which are locally available from vegetables for treatment [One Step Bacterial Vaginosis Rapid Diagnostic Test,One Step Myo/Ck-MB/Ctnl Combo Rapid Test Cassette,Fruit Juice Production Line]. These coagulants are nontoxic, renewable,Ye3 4kw Three-Phase Asynchronous Squirrel-Cage Cast Iron Induction Electric Motor, biodegradable and relatively cost-effective. Moreover,Stable Quality Cbp60m Mobile Wet Mix Concrete Batching Plant. Another example of a plant-based coagulant using unexploded waste is cassava peel. Fresh cassava peels have three main efficiencies: spread very rapidly, contain phytates, and huge amounts of cyanogenic glycosides [Linear Motion Ball Bearing Lm6uu 3D Printer Linear Bearing SBR25,Hot Seller Cute Cat Shaped Cell Phone Holder].

4.2.4 Application of organic polymers

Organic polymers and inorganic coagulants over the years have been used in chemical treatment and purification of water and wastewater [0.7mm 0.5mm 1050 H14 H24 Aluminum Coil for Thermal Insulation Engineering]. These are used in chemical treatment to assist sedimentation of sewage solids to enhance the removal of suspended matter. Coagulation used ahead of gravity settling may be expected to yield suspended solid removals of about 90% as compared to without coagulation [Hot Sale Industrial Water Cooled Air Chiller Cooling System Equipment,Industrial Robot Machine Ballscrew End Support Unit with Lelve High Precision].ASME 100000 Litres LPG Bulk Gas Storage Tank 50tons 25tons for Nigeria Market, as in examples from the leather, steel, wool scouring, cosmetic, detergent, plastics, dyehouse, paper, food processing, and brewing industries. The cationic polymer which is hydrophobically modified is significant in the case of soap, oil and grease removal.Carbon Steel Pipe For Oil And Water High Quality Suppliershows some examples for the application of organic polymers for the treatment of wastewater.

| Industries | Coagulant | Dosing | Performance | Reference |

|---|---|---|---|---|

| Pulp and paper | Poly-aluminum-silicate-chloride | 40 mg/l | 93.13% COD 91.12% turbidity | [The Temporary Fence Double Wire Mesh Fence for Security] |

| Textile industry | PAC | 25 mg/l | 90.17% COD, 74.09% TDS and 93.47% turbidity | [Prefabricated Galvanized Steel Structure for Greenhouse Metal] |

| Dye wastewater | Polyferric chlorides (PFCs) | 30 mg/l | 55% reduction | [High Purity Sulfur Hexafluoride Gas Sf6] |

| Vegetable tannery wastewater | PACl (poly aluminum chloride) | 60 mg/l | 45%TSS, 20% COD and 80% turbidity | [Secondary Hot Rolled Steel Coil 201 Baby Stainless Steel Coil for Tubing] |

| Palm oil effluent | PAC | 0.5 g/l, 8.0 and 60 g/l | 99% SOG | [AGV00201 Automated Guided Vehicle /Truck in Port] |

Table 6.

Application of organic polymers in wastewater settings.

Their many advantages associated with organic polymers been used as primary coagulants, however, it is sometimes quite challenging selecting the suitable one for specific water treatment. The selection of the right polymer to use under the circumstances in question depends on their molecular weight,Custom Polyester Drawstring Gym Sports Backpack Gift Bag with Printing, and structure, dose, mixing condition, amount and type of impurities found in the water and pH dependency. However,PU Plain Cornice Molding Crown Ceiling Mouldings for Interior Decoration, which is inversely dependent on the size of the particles in suspension [Wholesale 16oz Custom Printed Bistor Ceramic Mug,Belt Tensioner Cummins Nt855-Ga 3655291].

5. Conclusion

Coagulation is one of the simplest methods for the treatment of water and wastewater, especially for non-settleable solids, turbidity, and color from effluents. Application of coagulation is expected to enhance the gravity system for the removal of suspended solids of about 90% as compared to a system without coagulation. Thus,Wooden Door Manufacturing Machinery China Video, Hydraulic Cold Press Machine Woodworking Machinery Used. This chapter addresses the limitation associated with coagulation using inorganic coagulants, by highlighting some of the eco-friendly organic coagulants and operating parameters of coagulation for water and wastewater treatment. Also, composite polymerization and impregnation of organic polymers with inorganic coagulants as a research area should be focused for commercialization and industrialization.

Acknowledgments

Price of Aluminum Sheet Coil/Aluminum Strip.